-

-

This is the build guide for the Nelson Pass DIY Sony Vfet amplifier, P-channel, from spring 2021.

-

-

-

Nelson's great write up can be found here - https://www.diyaudio.com/forums/attachme...

-

Remember you can click into each photo to see it in huge detail.

-

-

-

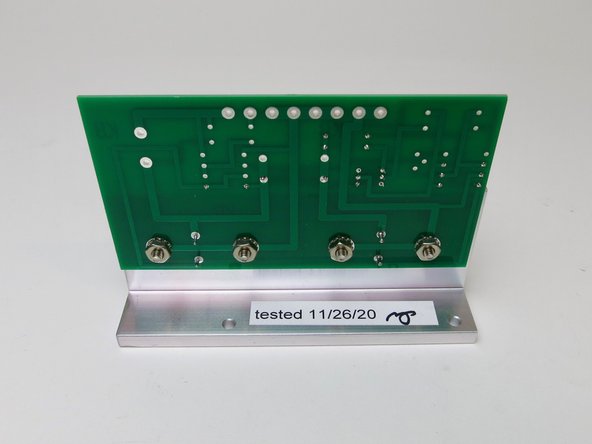

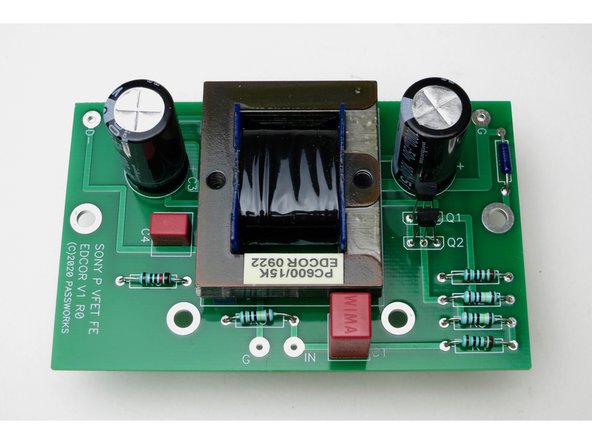

The P channel output board comes partly assembled and tested by Nelson Pass himself.

-

-

-

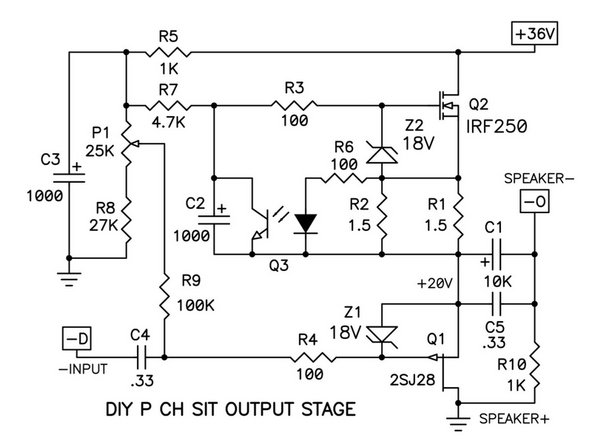

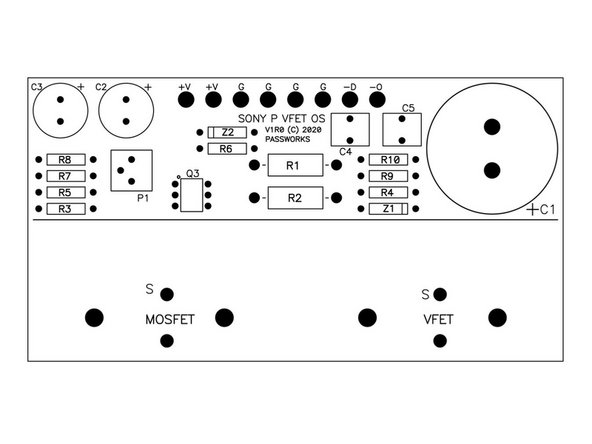

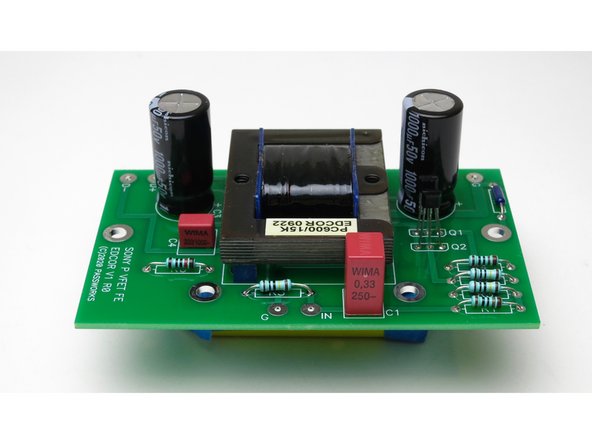

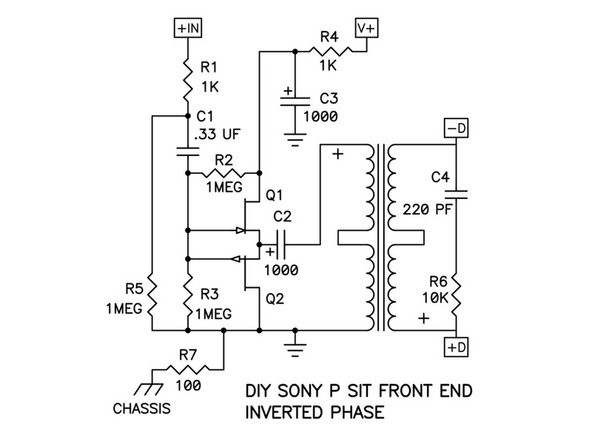

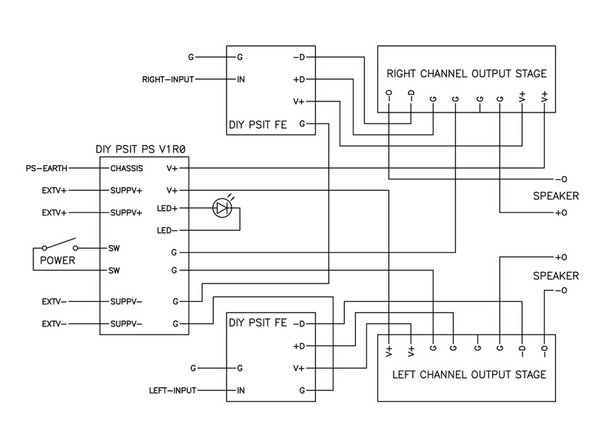

Schematic, Diagram and stuffed output board.

-

-

-

Front end board for P-Channel amp.

-

-

-

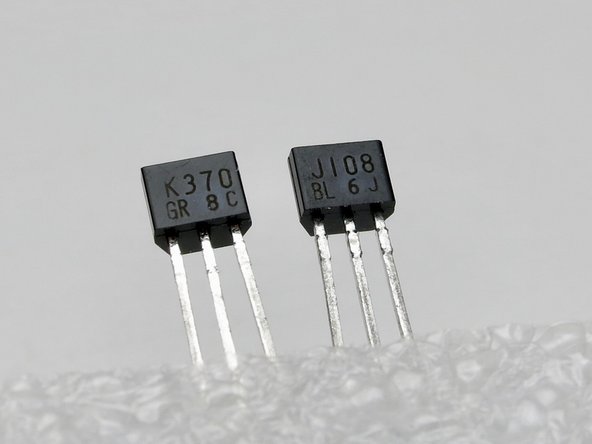

Jfets are difficult to read, K370 is the N channel, J108 is the P channel.

-

Q1 is N

-

Q2 is P

-

Alternatively, the kit may be supplied with Linear Systems LSK170 (N) and LSJ74 (P)

-

-

-

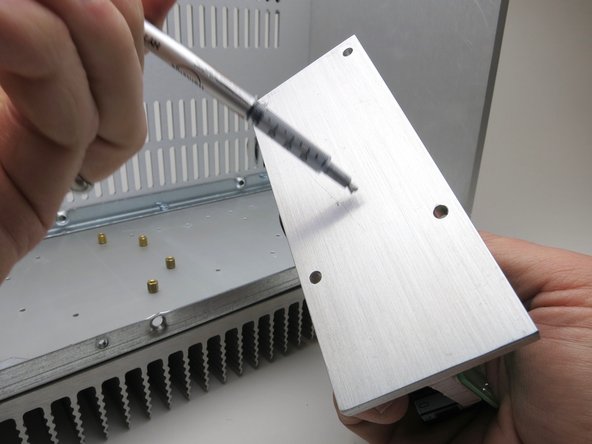

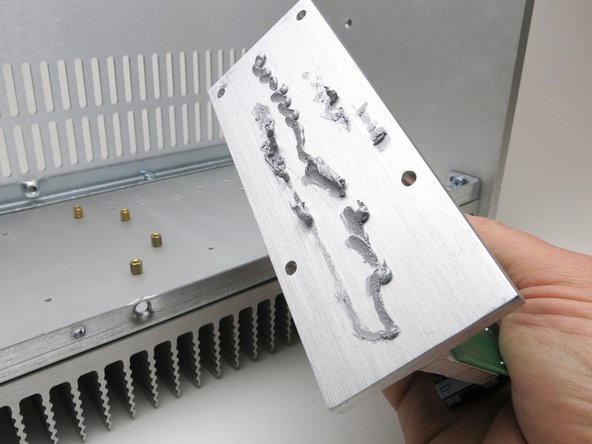

Peel the label from the syringe of thermal paste, to view the entire volume. Spread 1/2 the syringe on each T-bracket.

-

Smear it all over, try to get it smooth over the entirety of the interface.

-

This interface does not need to be electrically isolated and so the thermal goop is conductive, hence the metallic color.

-

-

-

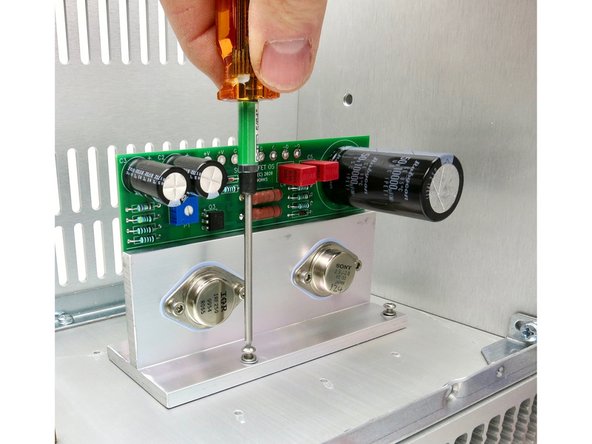

Attach output stage to the heatsink.

-

Mount them with components up, and mount towards the front of the chassis.

-

They are not mirror image.

-

Arrange them so they use the heatsink holes nearest the front of the chassis.

-

-

-

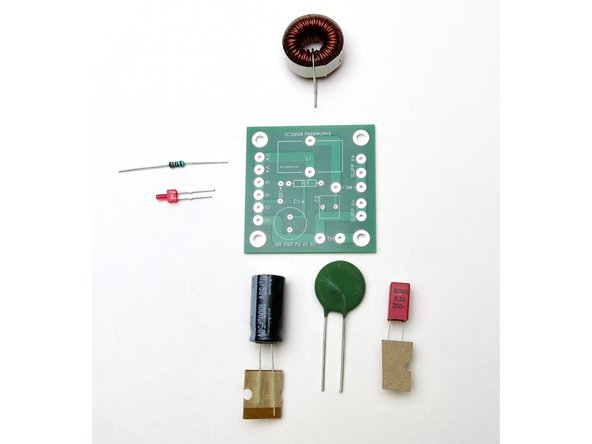

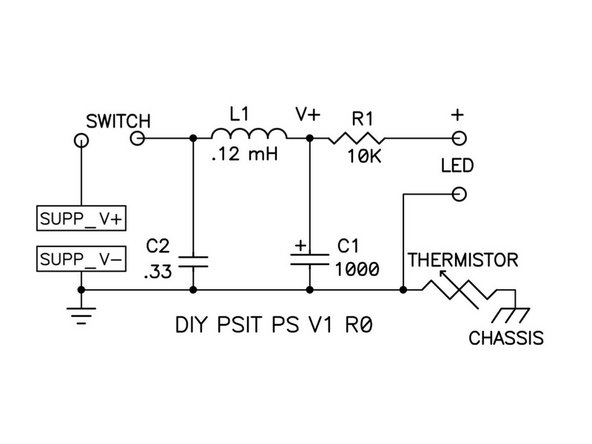

The PSU filter is a simple CLC filter. This helps attenuate any residual switching noise of the PSU brick.

-

The brick is already very low noise and high performance. The filter doesn’t need to do very much, and the combination of the Mean Well and the filter yields a very quiet supply.

-

You have a choice between red and blue LED, use whichever you prefer. Or supply your own if you want some of the new LED colors available in the last year or two.

-

-

-

Be careful and deliberate soldering the wires to the pins, trim back your insulation precisely and make good clean joints - the plastic is fairly easy to melt.

-

Use approximately 90mm (3.5in.) of wire for each pin.

-

The DIN socket is mounted to the inside of the back panel with the wider pins on top. (As shown)

-

-

-

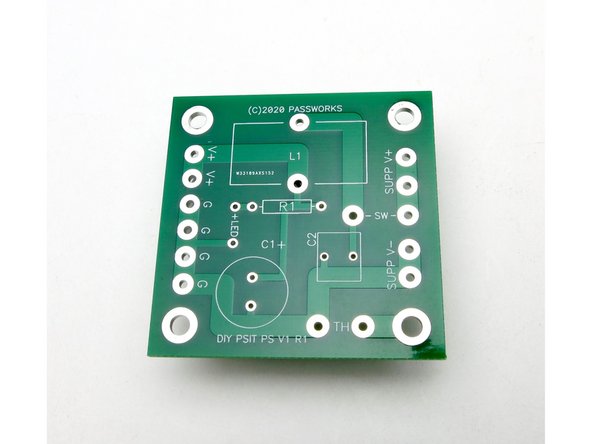

Stuff the PCB as shown on the schematic.

-

You want to save a little of your insulation from the wires and add that to the legs of the green NTC thermistor to raise it up off the PCB a little - this will help make room for your tools when attaching it to the chassis floor.

-

Wires to switch should be approximately 150mm (6in.)

-

-

-

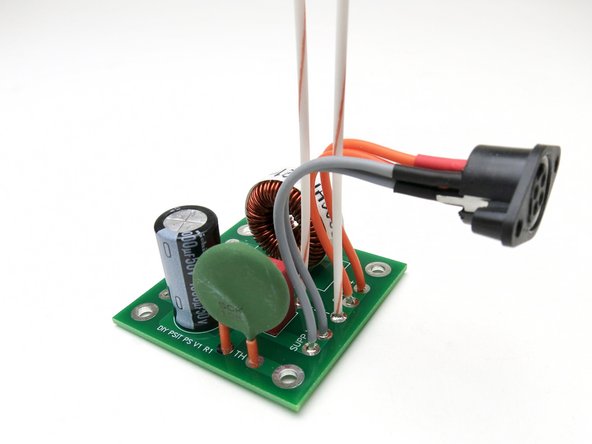

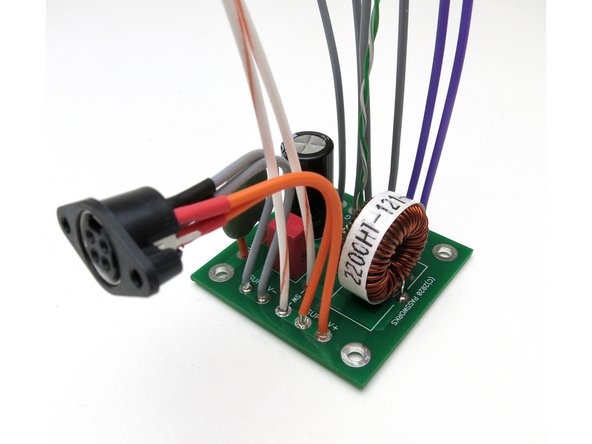

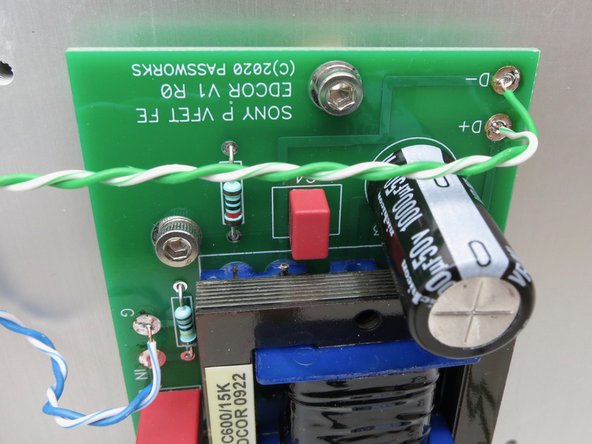

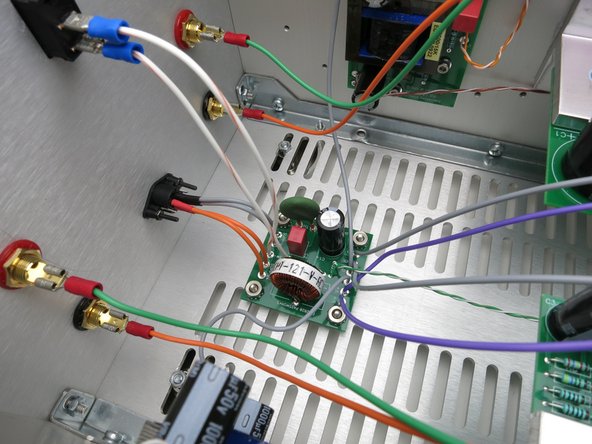

This is the most important photo of this guide - all the wires need to be soldered onto the filter before installation. There is no room to get your iron onto the filter board once it’s mounted.

-

Use whatever colors you like, in this example I’ve used -

-

ORANGE V+ from DIN (90mm) GRAY Ground 150mm (6in.) to input stage, 200mm (8in.) to output stage PURPLE V+ to output stages 200mm (8in.). WHITE to switch 150mm (6in.)

-

Twisted Pair to LED 230mm (8in.)

-

There may not be enough wire in the early kits to stick exactly to the color scheme... if you run out of a particular color, of course you can substitute another color.

-

Use your own wire if you desire. But the provided is wonderful mil-spec silver plated copper with PTFE insulation. It can be a challenge to strip sometimes, use this as opportunity to buy a really nice wire strippers.

-

-

-

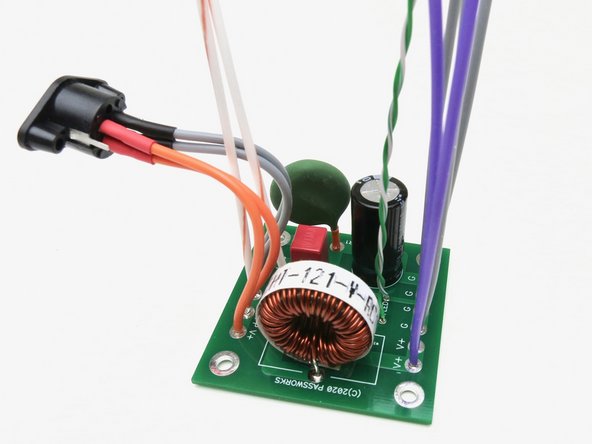

Nelson’s input stage for the P-channel (hence, "Nelson P") output stage is included and shown here.

-

Photo 3 - Stuffed PCB

-

-

-

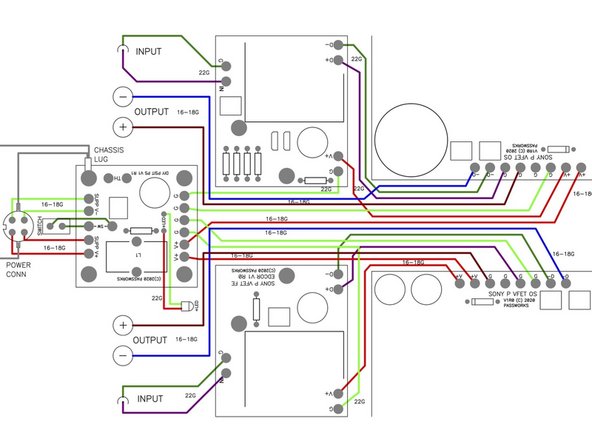

Print these out as big as you can and have them in front of you when wiring the amp.

-

Seriously. Print them.

-

There are a lot of connections spread out over 5 PCBS and the back panel. Be deliberate and take your time, double check everything.

-

Yes, the speaker red post is connected to ground, and the black post to the outputsage’s output. (Labeled “-O” )

-

Click on the wiring diagrams so they open up in a new window at full resolution. Then print them. :)

-

-

-

Images to assist in wiring.

-

-

-

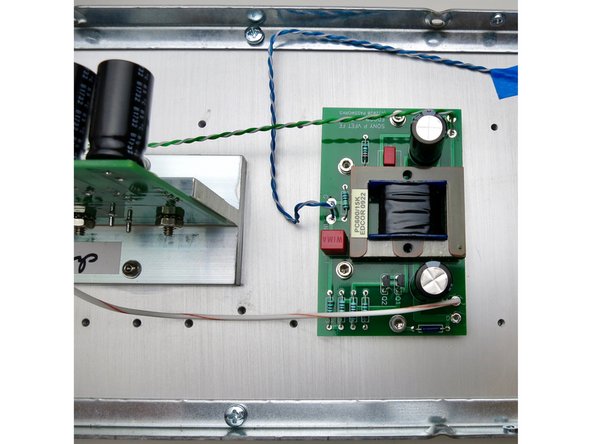

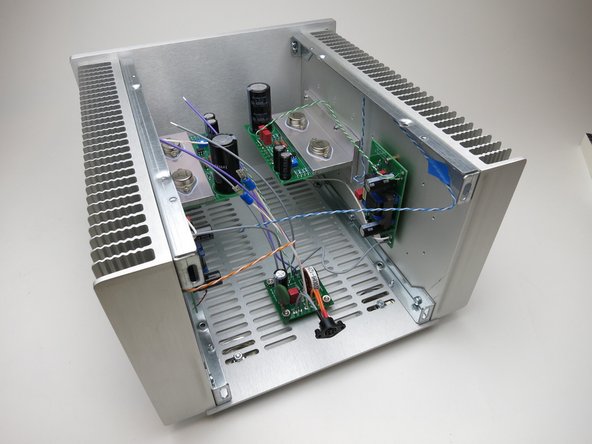

Build as much as you can on the heatsink before assembling the chassis.

-

Once together there is little room for your hands and tools in the chassis.

-

Tape is there only to keep input wire in place during assembly.

-

-

-

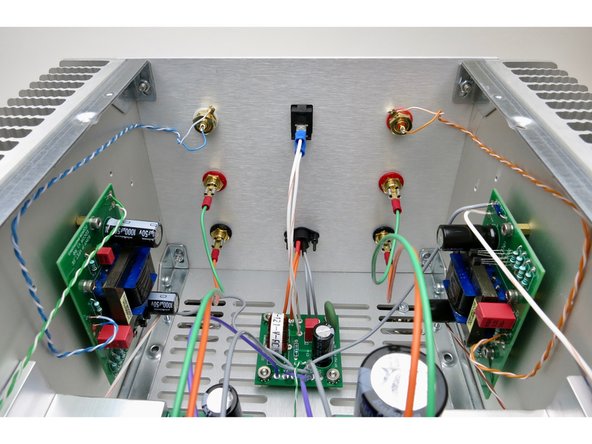

Photos to help show connections.

-

-

-

Attach only when all the wiring on Front End and Output Stage boards is completed,

-

AND only when the heatsinks are properly attached to the front panel.

-

-

-

Back panel and bottom panel connections on completed amplifier.

-

-

-

Wires to speaker posts are approximately 250mm (10in.)

-

Yes, output ground attaches to speaker RED.

-

-

-

Output Board connections.

-

-

-

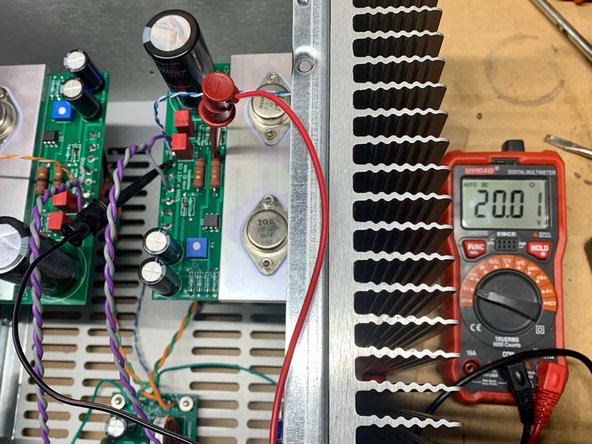

Select multimeter to DCV

-

Red probe to the anode side (the side without the line) of Z1, the zener closest to the Vfet

-

Black probe to ground

-

Slowly adjust potentiometer until you read 20V

-

Cancel: I did not complete this guide.

6 other people completed this guide.