-

-

Guide under construction.

-

The body of the guide is 90% complete at this time.

-

-

-

A fantastic kit of parts available with all the components, hardware, fasteners and PSU.

-

Although some of the aesthetics of the parts do not match the photos in the guide, they are electrically and qualitatively a 1:1 match.

-

-

-

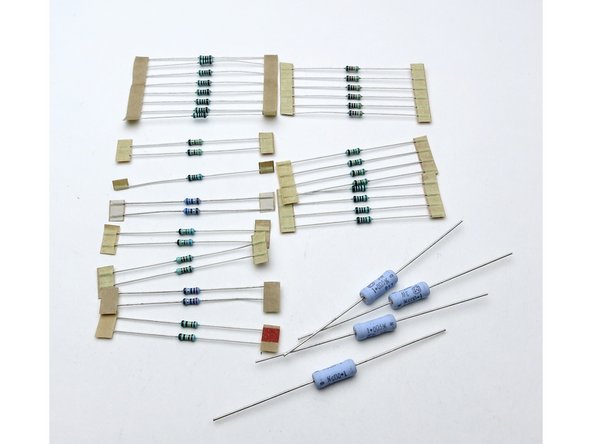

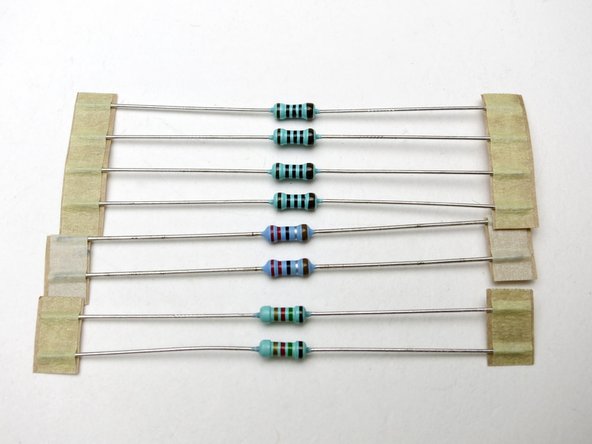

Photo 1 - Resistors

-

Photo 2 - Capacitors

-

Photo 3 - Semiconductors

-

-

-

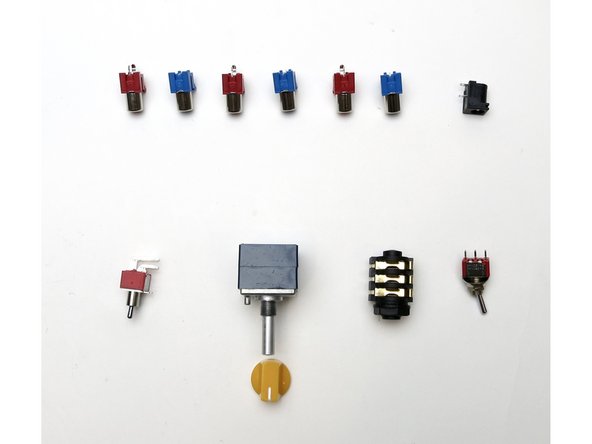

Photo 1 - Jacks, switches, and Potentiometer. (Red are incorrect style to fit PCB , this photo will be updated)

-

Photo 2 - Example 24VDC power supply with 5.5x2.1mm plug.

-

-

-

Large - Groundplane attachment bolts Small - Mosfet attach bolts

-

Heatsinks and stick-on feet

-

-

-

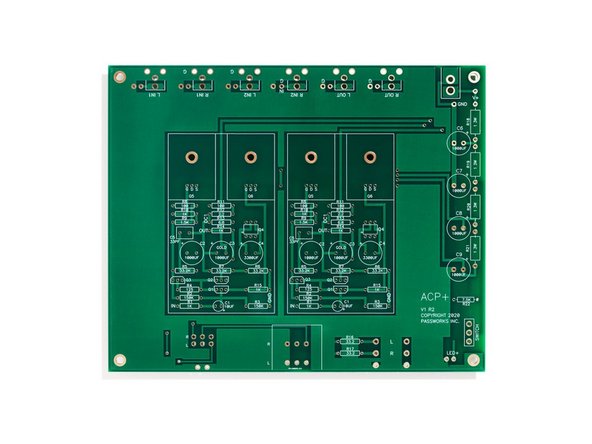

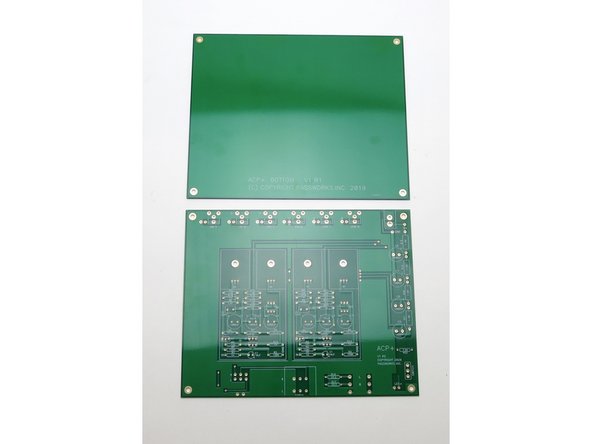

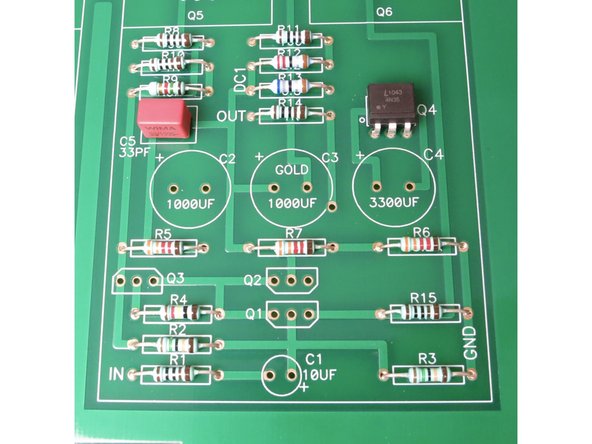

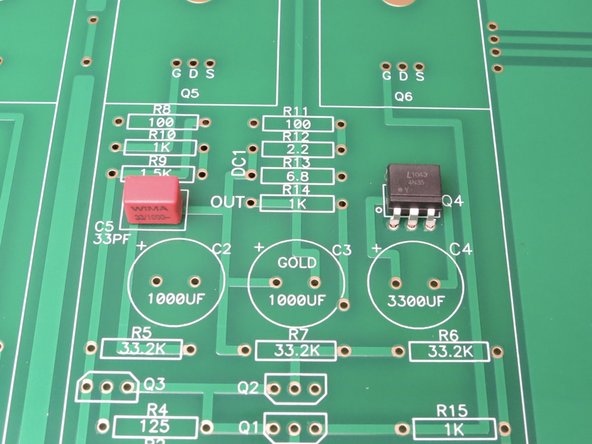

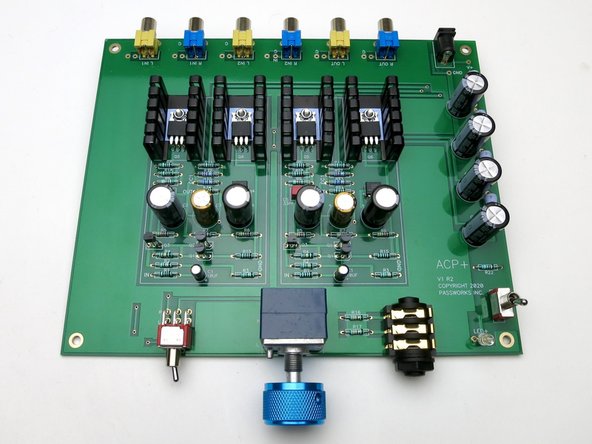

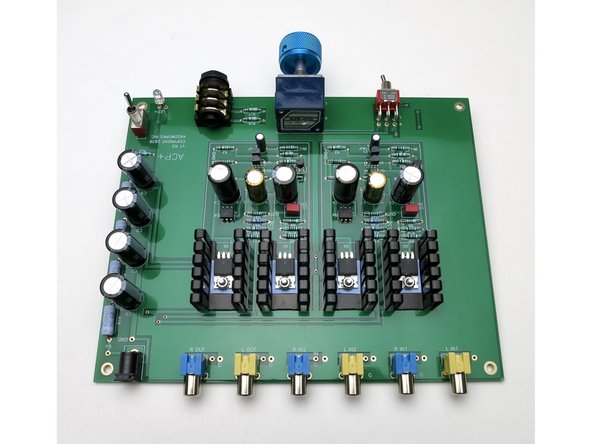

Circuit PCB

-

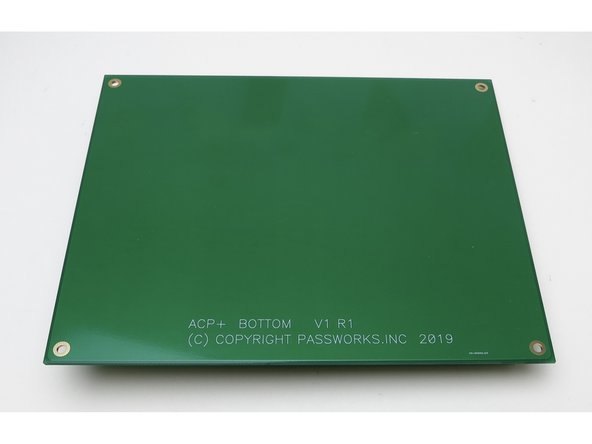

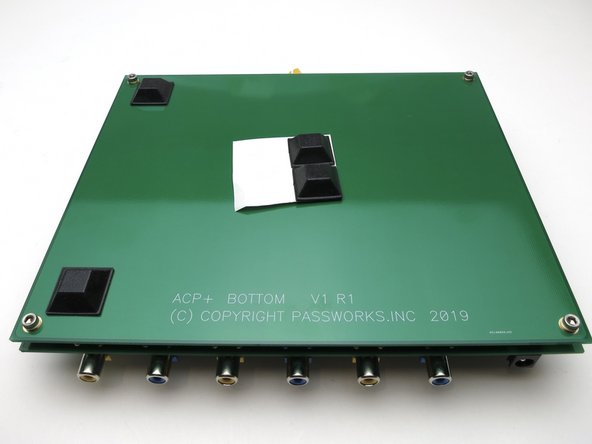

Ground Plane board

-

Both are the same size

-

Note: If you plan on building this without a chassis (I.E., as shown...) you must use the ground plane.

-

-

-

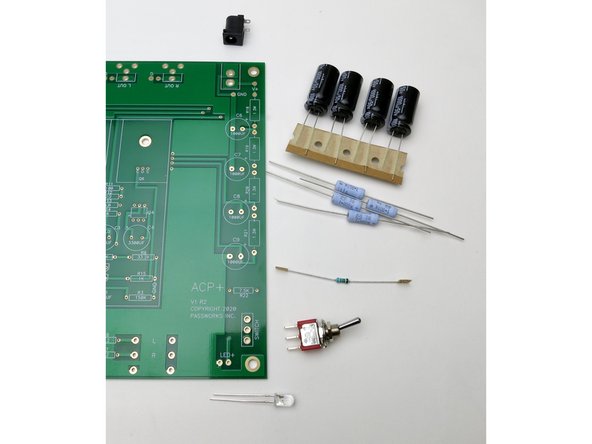

Gather these components

-

Stuff PCB smallest to largest, resistors, then power jack,

-

-

-

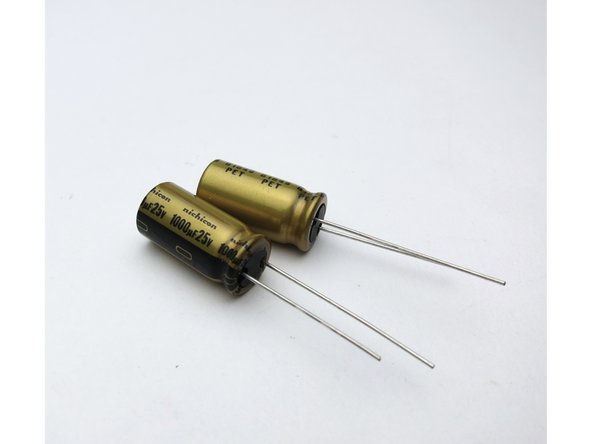

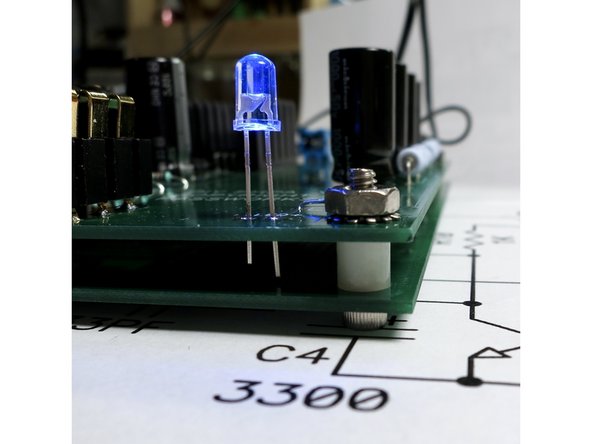

Capacitors are polarized.

-

The Negative side is marked on the can

-

The positive lead is longer

-

The PCB has a "+" marked for the positive lead

-

Finish stuffing PSU capacitors and watch polarity.

-

-

-

Add testing procedure

-

-

-

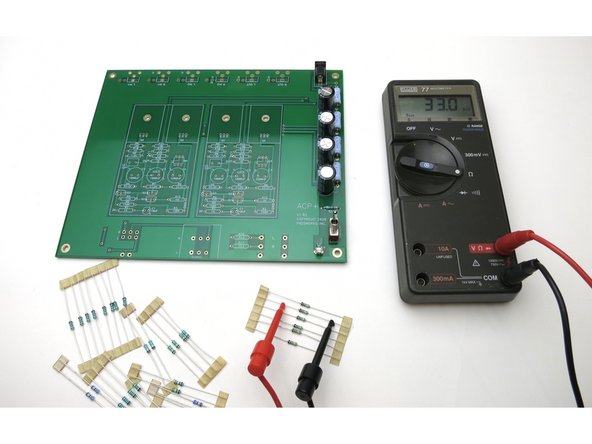

Measure all resistors before inserting into the PCB. This greatly reduces errors during construction.

-

-

-

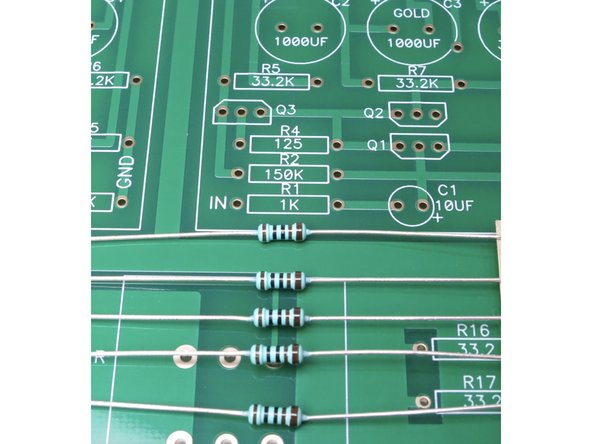

All smaller resistors are on a 0.5 inch lead spacing. A lead bender tool is recommended.

-

Remember, stuff resistors with the brown band to the right.

-

-

-

Stuff resistors with the slightly thicker brown band to the right.

-

-

-

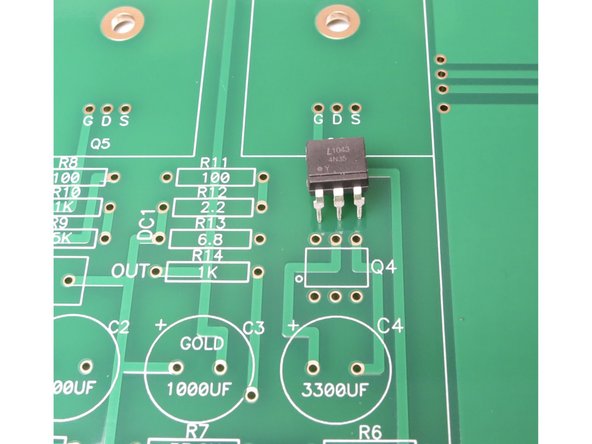

Optocoupler has a dot at pin 1, this aligns with dot on PCB

-

-

-

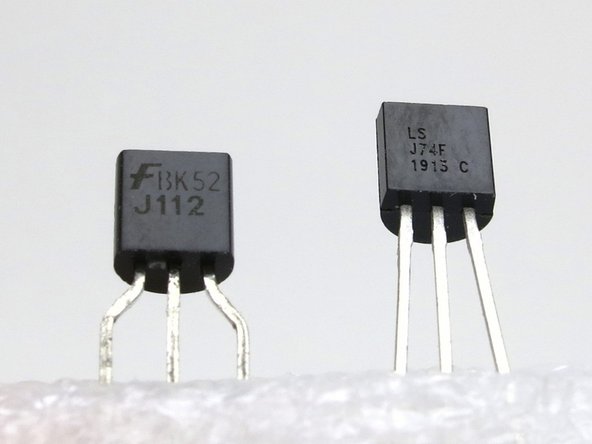

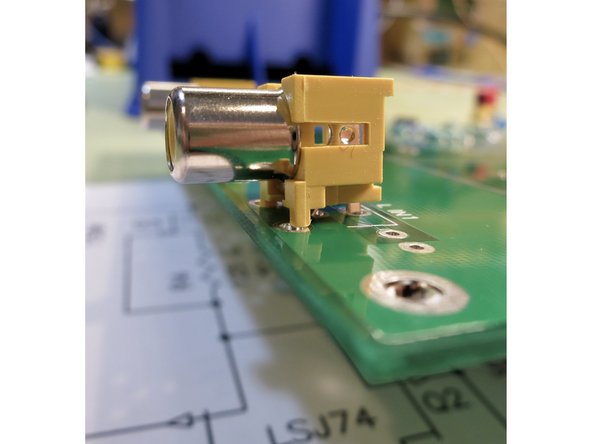

Left side J112.

-

Right side LSJ74.

-

J74s in this circuit need to be matched.

-

-

-

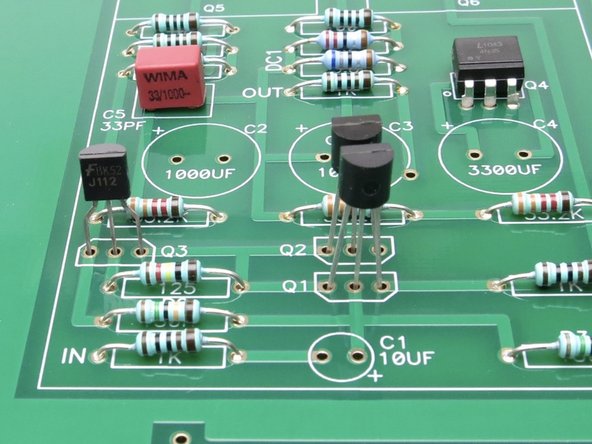

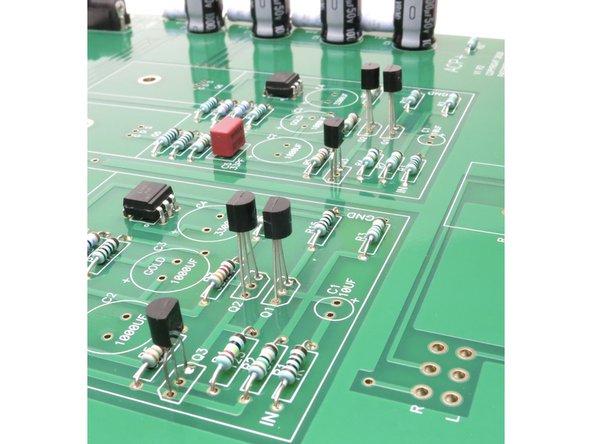

The flat of the transistors aligns with the flat of the transistor mark on the silkscreen.

-

Q2, Q2 are a matched pair of LSJ74

-

Q3 is a J113 selected for Vp of 2.5v, +/- 1v

-

-

-

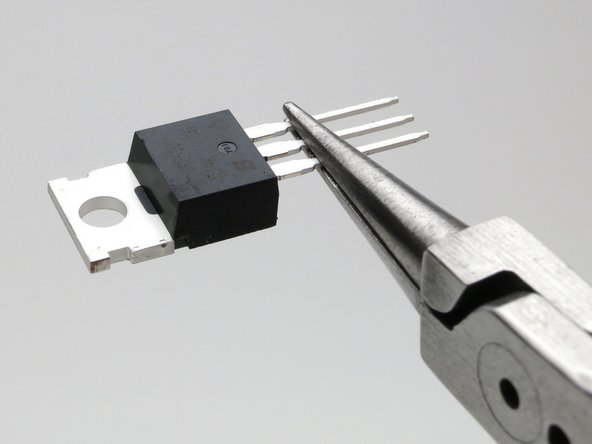

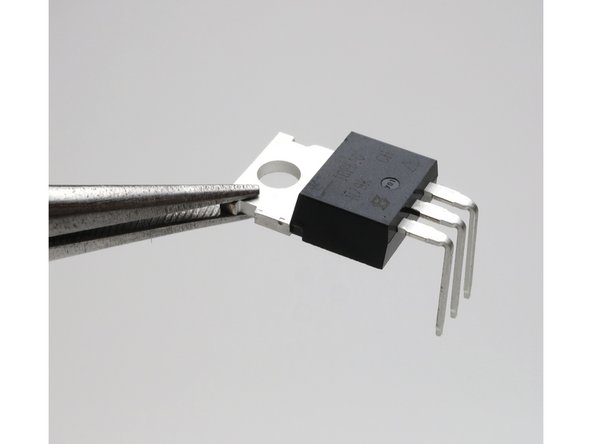

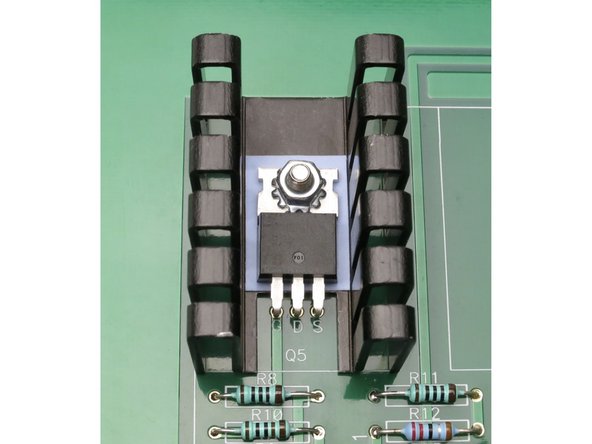

Bend legs down at point shown.

-

-

-

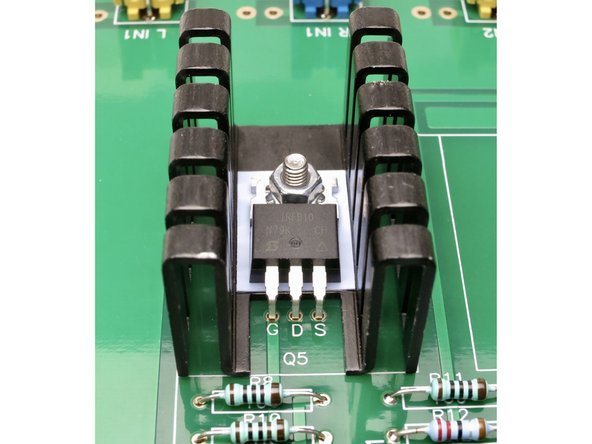

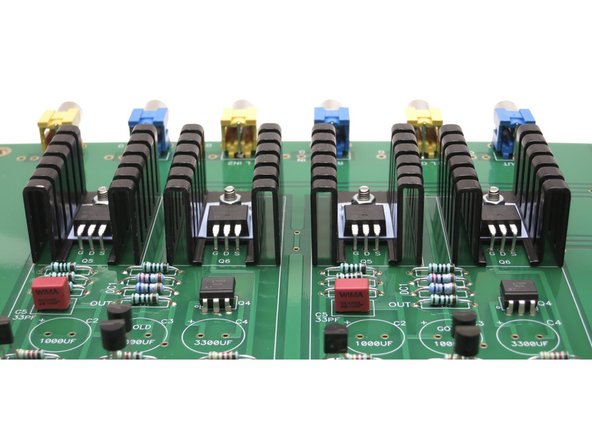

Thermal interface (pad or paste) not strictly required, but not a bad idea.

-

Mosfets do not need to be electrically isolated from the heatsinks.

-

Make sure heatsinks are aligned and do not touch each other.

-

-

-

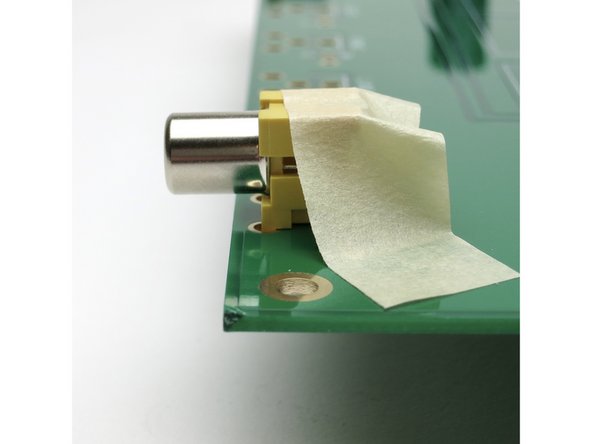

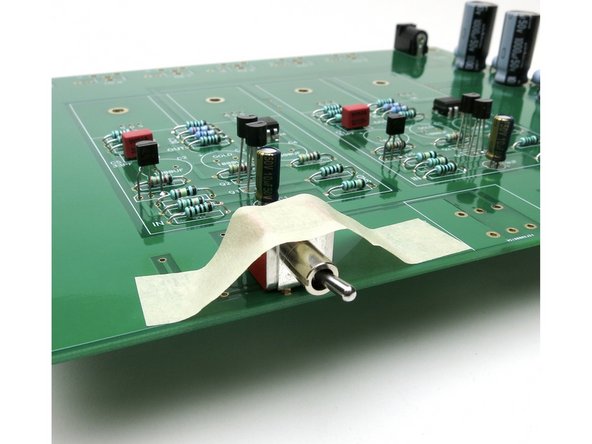

A bit of tape will hold the jack completely flat on the PCB for soldering.

-

Photo 3 - Improper alignment. Make sure the jack is entirely flat on the PCB before soldering.

-

-

-

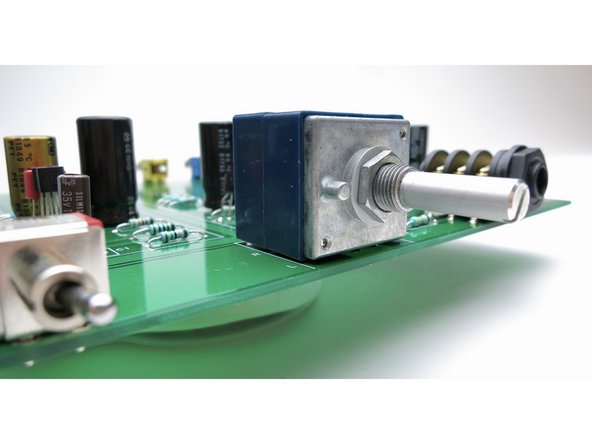

Maker sure potentiometer is flat on the PCB before soldering.

-

-

-

Make sure the switch is flat and flush with the PCB before soldering

-

-

-

Insert wisdom here.

-

-

-

Screw from bottom, spacer in-between, nut on top.

-

-

-

Place as shown

-

Cancel: I did not complete this guide.

10 other people completed this guide.