Introduction

What Are We Building?

This guide covers the assembly of a stereo Nelson Pass F5M amplifier with a single power supply. It features parts from the F5M Core and PSU kit from diyAudio store along with the diyAudio Deluxe 2U chassis. It demonstrates a lower bias build in a slightly more compact chassis.

|

What Is Covered In The Guide?

This is a build 'guide'. It is not an instruction manual. The purpose is to assist in learning and guide DIYers with helpful information. Builders should not expect every detail to be covered.

|

It is not the only information needed to complete the project. Some additional links are included as guidance. It is critical to understand that the guide is an EXAMPLE of how to complete the project. It is not the ONLY way to complete the project. DIY is all about choosing your own adventure. Have fun!

|

The project is considered moderately difficult. The guide is not intended to instruct someone that has never built an audio amplifier through their first project. This guide is best suited to someone with an interest in audio electronics that has built one or two audio projects, and is ready to take the next step or just needs a few helpful hints.

|

Builders should have a basic knowledge of electronics and should be proficient in through-hole PCB soldering. Although there are many helpful tips throughout the guide, before attempting to build this project, the builder should be confident in their ability to:

- SAFELY work with electronics powered with mains voltage,

- follow a schematic and identify the proper placement of parts from the schematic onto the PCB,

- understand basic measurements to identify parts correctly, and

- properly solder a variety of through-hole components.

|

What Else Do You Need?

There is a list of major parts used in the example, and a list of tools has been provided.

|

All critical parts are noted, but this is an advanced project, and not every part is included with the kits. Not every tool you may need for your personal build is noted. At times, other parts and tools used in the guide are noted. However, this is DIY; builders can and should improvise. Links are provided in the Tools & Parts section for examples of most of the tools and parts required to complete this project, but the options are limitless.

Most importantly, if you have questions, please seek help in the forum.

Enjoy!!!

Tools

-

-

A black bullet is explanatory or contains valuable information.

-

Everything in this guide is important, but here's how you'll know something is REALLY important.

-

A green bullet is the mark to do something.

-

A yellow bullet indicates a fun fact.

-

Warnings will be noted with a warning symbol and bold, red, underlined text. Pay Attention!

-

Tips and tricks and helpful reminders will be noted with an information bullet.

-

Photo / Image captions and information will be noted with the Photo/Image Icon.

-

-

-

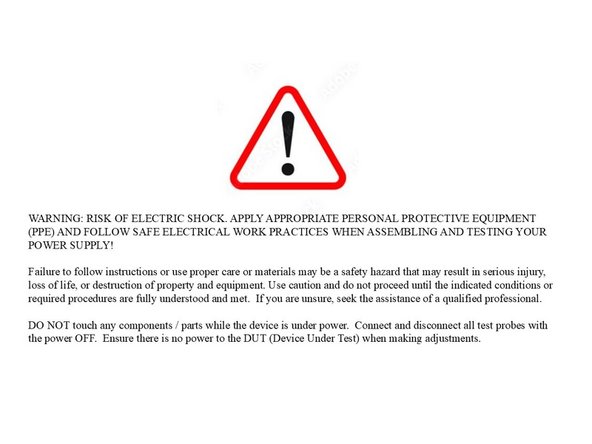

Click on the image to enlarge and read the warnings carefully.

-

-

-

Your first "real" black bullet. You may notice that you have the option to view in "Full Screen". This web platform works well with tablets too. It has been tested it with various monitors of various aspect ratios and tablets. Choose what looks best to you. The printed .pdf format is nice too.

-

Image 1 - To switch to "Full screen", take note of the box around "Full screen" at the top of the guide above the header / title. That's where you click to move to Full Screen.

-

Image 2 - Note that you can download this guide as a .pdf and print it. Click the options button in the upper right.

-

In all the on-line views, if there are multiple images and/or photos within a step, mouse-over or tap/click as appropriate to make which ever one you'd like the primary image (the biggest one).

-

Mousing over / tapping on the primary image will change the cursor to a magnifying glass. Clicking / double tapping will open a new tab or enlarge and center the image on your screen.

-

In full-screen mode, the keyboard right and left arrows or clicking the arrows in the upper right of your screen will advance or reverse one step.

-

Your first "real" green bullet. Choose if you want to view in full screen or standard (if you haven't already) and/or print a copy of the guide.

-

Get started. Move on to step 4.

-

-

-

All mistakes are preventable, and this guide moves slowly through each step.

-

The most common issues with builds are mis-stuffed parts and poor solder joints.

-

Symptoms from mis-stuffed parts typically manifest quickly. For this build, pay particular attention to the small resistors and the TO-92 packaged transistors. The impact from an improper part placement can be benign, or you could release the "magic smoke".

-

The impact of poor soldering varies. A short/bridge that will impact your build is unlikely, but can be catastrophic. More commonly, the issues are partial coverage or a cold joint. Symptoms may not manifest until you least expect them, and they may be intermittent. Inspect each and every joint under magnification. You'll be glad you did.

-

DMM issues can lead to frustration.

-

Check the batteries. When in doubt, replace the batteries.

-

Make sure your probes are reading "0 Ohms" resistance probe to probe or are appropriately compensated.

-

Make sure your probes are connected properly and free of finger oils. A quick wipe with IPA will clean them nicely. For this guide, the polarity of the voltage being read isn't critical, but it's best practice to understand the polarity. As an example, if you are troubleshooting an issue, it is likely that the polarity will matter.

-

-

-

The notation of voltages requiring a decimal place will have a "V" in place of the decimal. 24V5 is 24.5 Volts or 24,5 Volts.

-

The notation of resistance requiring a decimal place will have a "R" in place of the decimal. 0R5 is 0.5 Ohms or 0,5 Ohms.

-

The notation of Amperage requiring a decimal place will have an "A" in place of the decimal. 1A1 is 1.1 or 1,1 Amperes.

-

-

-

The most common action you'll take throughout the guide is to "install" your parts AKA stuff the PCB. Parts installation includes:

-

Ensuring you have the correct parts to match the PCB silkscreen / schematic.

-

Ensuring the leads are clean / free from finger oils, and are bent to the proper pitch (if applicable).

-

Validating the orientation of the part (as applicable) and inserting the part into the boards along with ensuring any vertical spacing (as applicable).

-

Soldering the parts into place.

-

Cutting the leads to the proper length*

-

It is also acceptable to clip the leads to the correct length prior to soldering. There are compelling reasons to do it either way. If you are unsure, watch a few videos, read a few articles, and do some test soldering of your own to see what works best for you. If you choose to clip prior to soldering, use the correct tool.

-

Cleaning and inspecting the joint. It is strongly recommended to use magnification and good lighting to inspect each and every joint.

-

-

-

This guide does not cover how to solder / install through hole parts. There are a variety of great ways to install a part and achieve a proper solder joint, but there are common themes throughout. Below are a few links. See what works best for you. Neither diyAudio nor the author have any affiliation with any of the companies or persons linked.

-

-

-

-

-

Image 1 - A basic soldering sequence and examples of both good and poor joints. Taken from the Rayming PCB & Assembly Guide linked above.

-

The key variables to soldering are the type of solder chosen, the tip used, and the tip temperature. These all vary widely between users and are inter-related. If you are new to electronics, the best solution is practice. Scrap electronics and inexpensive parts are a wonderful way to learn.

-

Leaving the iron tip on the joint for longer than around 5 seconds is not a substitute for too small an iron tip or too low a temperature. If you need to reflow a joint, or if the solder isn't flowing, flux is your friend.

-

-

-

Plan your build. Read this guide a few times before you even take the first part out of the bag.

-

Go slowly. You're not getting paid to do 100 boards a day. This should be relaxing and fun. A lot of errors can be traced back to lack of attention and rushing.

-

The ONLY parts within reach should be for the step you are working on at the moment. Many parts look very similar.

-

Move the boards and your body around to give yourself the best angle to solder each part. Get close to your work and use magnification. A well-lit workspace is important. You don't stand a chance if you can't see.

-

Before moving to the next part, triple check your work. Hopefully you won't make any errors, but it is much easier to remove one part than many to fix an error. Using the included documents and following a basic sequence will assist with error-free construction.

-

Take plenty of breaks and stop at any point confusion or frustration sets in. There are a few recommended stopping points throughout the guide, but stop any time you mentally or physically need to recharge.

-

Try to keep distractions to a minimum.

-

Neatness counts!!! Take pride in your work. You'll be happy you did.

-

-

-

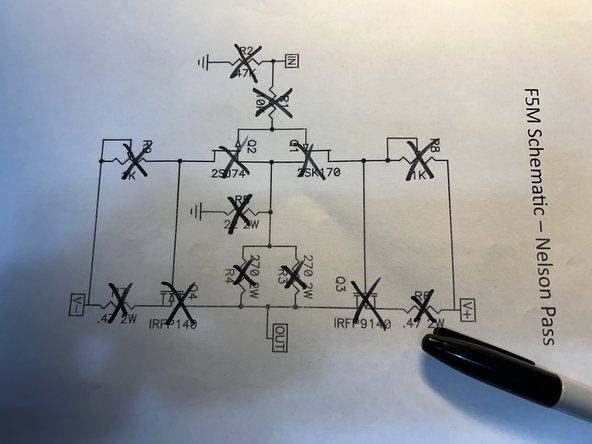

Print a copies of each the schematics found at the end of this guide or in the Documents Tab if you are viewing in Full-Screen Mode. You'll need to go back to the Introduction (full-screen mode) or scroll to the end of the guide to find the documents / documents tab.

-

Note - Schematics are not representative of the board layout. The schematic is not an overlay for the boards / traces / parts.

-

Tidy up your workspace. Keep in mind that you'll be working with a very hot soldering iron, and it can be easy to misplace parts. A few recommendations:

-

No other parts for any other projects should be within arm's reach.

-

The floor and the area around the workspace should be clean, just in case a part escapes. The kits contain small parts. It can be very frustrating to wait several days for a single part if you lose one.

-

-

-

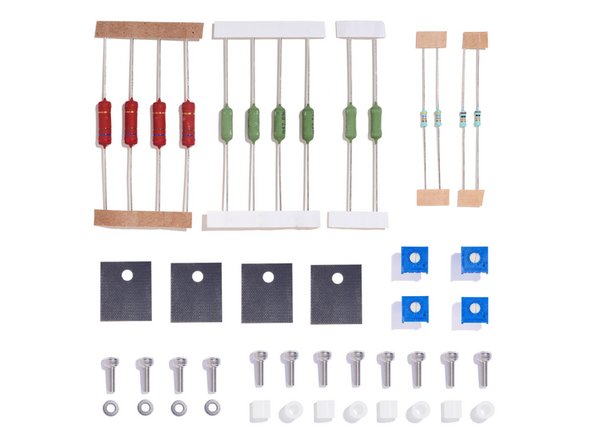

Find a clean, open space on your workbench and open the Essentials Kit. Take care to not drop any parts. It's a good practice to empty parts into a bowl.

-

Photo 1 - Essentials Kit Parts Bag

-

Photo 2 - All the parts you should receive

-

Note - The part lot numbers and manufacturers will change over time.

-

-

-

Find a clean, open space on your workbench and open the Completion Kit. Pour the contents into a bowl. Check that you have all the parts. Since there are so few parts, they can be measured/validated as you check them off. The spacers are small and will wander off. Keep track of them!

-

Photo 1 - Supplemental Kit Parts Bag

-

Photo 2 - All the parts you should have

-

Note - The part lot numbers and manufacturers will change over time.

-

-

-

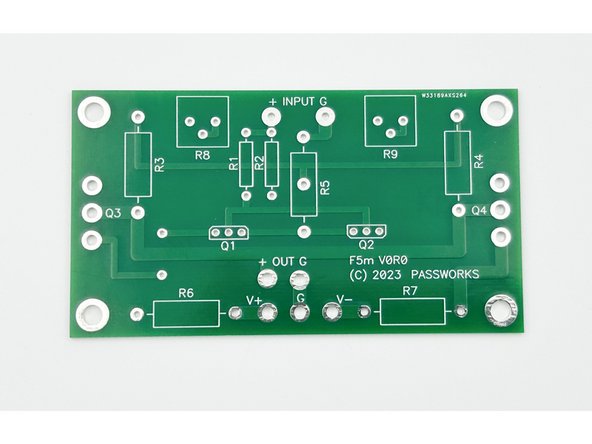

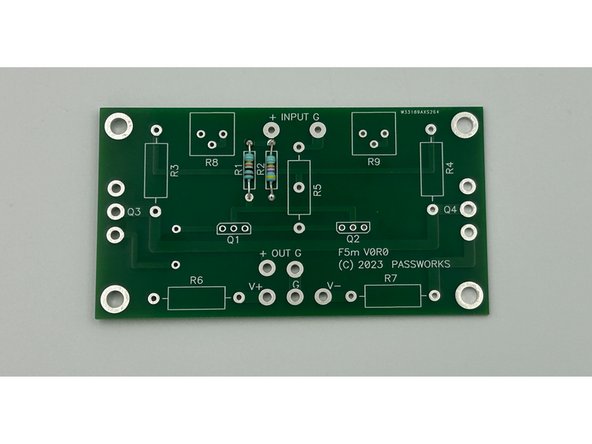

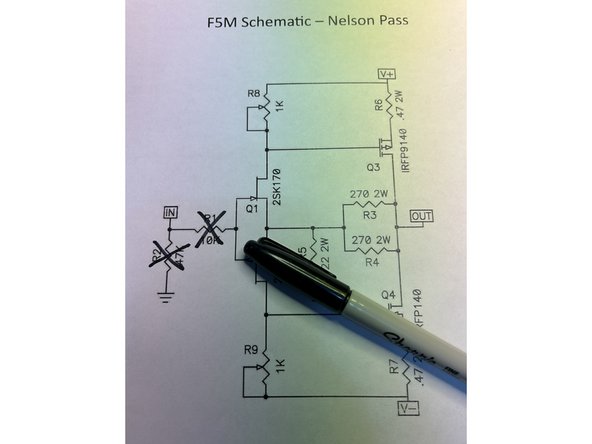

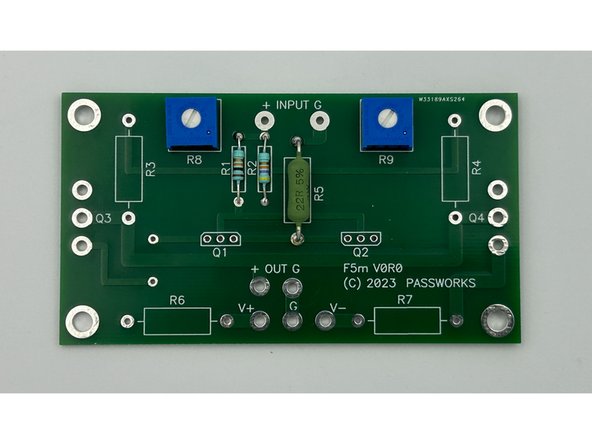

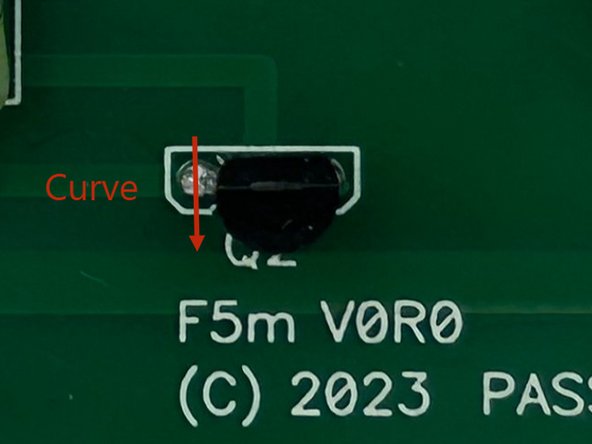

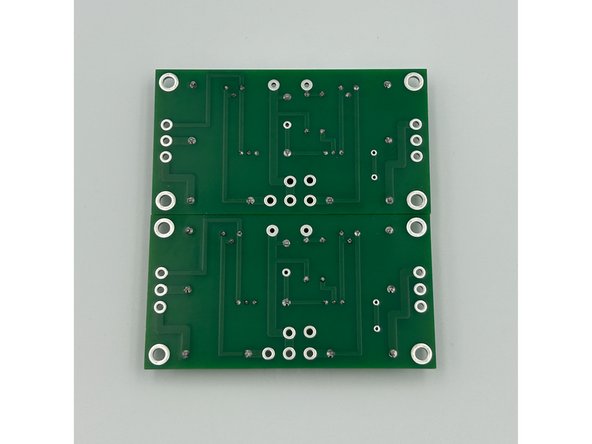

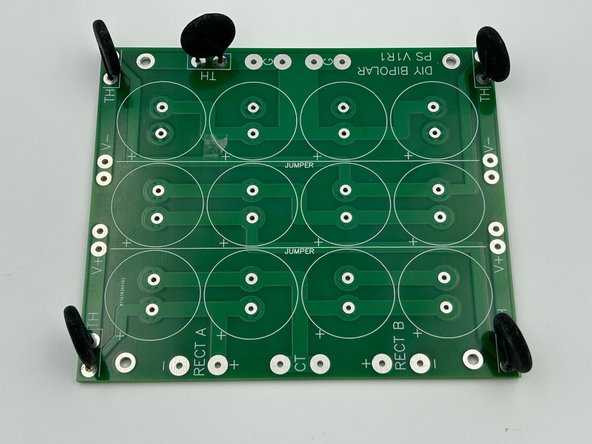

Look over your boards and get familiar with the parts placement. Check the board against the schematic.

-

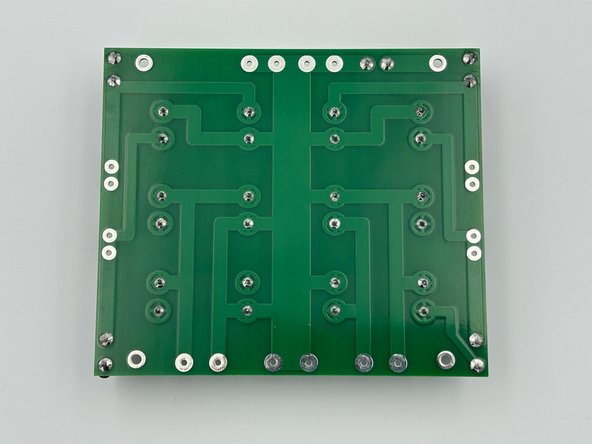

Image 1 - Front view of the PCB.

-

Image 2 - Back view of the PCB, sometimes referred to as the solder side. You will not install any components on the back of the board.

-

Clean both sides of the board with isopropyl alcohol or your favorite PCB cleaner. A dust and oil free board helps the solder to flow nicely.

-

Ambitious DIYers may trace the board with a DMM in continuity mode against the schematic. It's not necessary, we've done it for you, but give it a try.

-

-

-

There are 13 components to solder for each board. It is good practice to install the shortest / lowest components first and work from the interior of the board to the edges. It makes life easier. Because the MOSFETs need to be mounted to the heatsinks, and you will need to do some wiring, they'll come later. The initial order is:

-

2X - Small, banded resistors - R1 and R2

-

2X - Single-Turn Trimpots - R8 and R9

-

1X - Green, 22R, Big Resistor - R5

-

2X - Green, 0R47, Big Resistors, R6 and R7

-

2X - Orange, Banded Resistors - R3 and R4

-

2X - JFETs - Q1 and Q2

-

-

-

Remember to measure the resistance for every part before installation.

-

It is helpful to use a lead forming tool. The pitch for the small resistors is 1/2"

-

Having all the resistors oriented the same way helps tremendously with troubleshooting. In this build, the bands will read from left to right or bottom to top. The thick brown band is "band 5" for these resistors.

-

Install all the small resistors, R1 and R2 for both boards.

-

Photo 1 - When all of the small resistors are installed, your board should look like this.

-

Photo 2 - It is good practice to tick off the components on the schematic as they are installed.

-

-

-

Pay attention to the silkscreen outline and the staggered pins to ensure the proper placement. If the pins are bent, gently straighten them before installation.

-

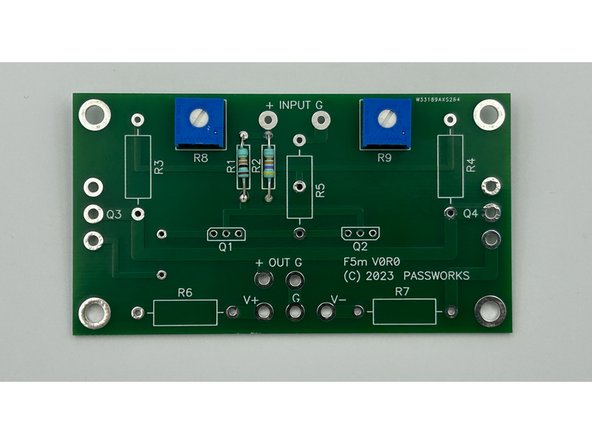

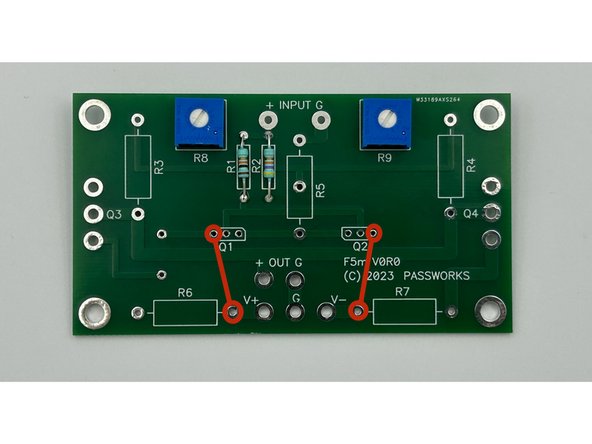

Install R8 and R9 on both boards and turn both pots fully counter-clockwise (CCW).

-

Photo 1 - Pots installed

-

Photo 2 - Test points

-

Using your DMM set to resistance, place the probes on the pads circled in Photo 2 for Q1 and V+. Ensure the resistance is close to 0 Ohms. Turn the pot fully clockwise (CW) and ensure the resistance is close to 1kR, 1,000 (one-thousand) Ohms.

-

Using your DMM set to resistance, place the probes on the pads circled in Photo 2 for Q2 and V-. Ensure the resistance is close to 0 Ohms. Turn the pot fully clockwise and ensure the resistance is close to to 1kR, 1,000 (one-thousand) Ohms.

-

If you are using pots not included with the kit. Ensure that you know which direction results in an increase in resistance between those two points and make a note. If turning the pots CCW results in higher resistance. Invert all future instructions. When it says to turn CW, you will turn CCW and vice versa.

-

Set the pots fully counter clockwise.

-

-

-

Note - When measuring the resistance of the 0R47 resistors, you're likely not going to get a very accurate reading unless you've got an expensive DMM and know how to use it properly. Handheld DMMs usually struggle below 1 Ohm. Don't worry about it. The value is marked clearly.

-

A lead forming tool is helpful. The pitch for all the large resistors is 3/4". Bend the leads, so the value will be facing up when the resistor is installed. It's good practice. Neatness counts!

-

These resistors get hot. Raising them above the PCB allows air to flow around them, which keeps them a little cooler. You can use whatever you have around to raise them. Many builders use a tongue depressor / popsicle stick. A few mm above the board is perfect.

-

Install R5 on both boards

-

Install R3 and R4 on both boards

-

Install R6 and R7 on both boards

-

Photos 1, 2, and 3 - Installation of R5; R6 and R7; and R3 and R4.

-

-

-

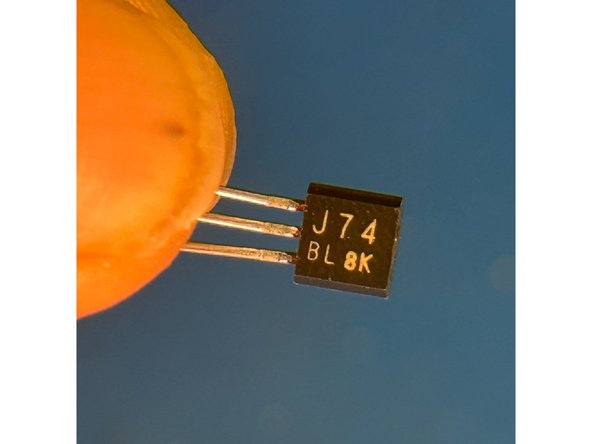

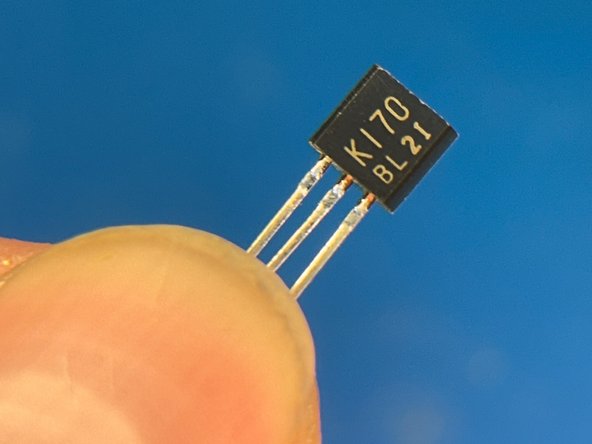

Your kit comes with 2 types of JFETs (4 Parts Total) in a TO-92 package. These are your rare Toshiba JFETs. They all look similar to the naked eye. It is critical to validate each part. Best practice is to check the case marking and measure the part. However, a visual confirmation is acceptable.

-

Using any appropriate magnification, separate the transistors marked K170 from the transistors marked J74.

-

Photo 1 - A 2SJ74 P-channel JFET.

-

Photo 2 - A 2SK170 N-channel JFET

-

Note - The lot codes will likely be different from the photos.

-

-

-

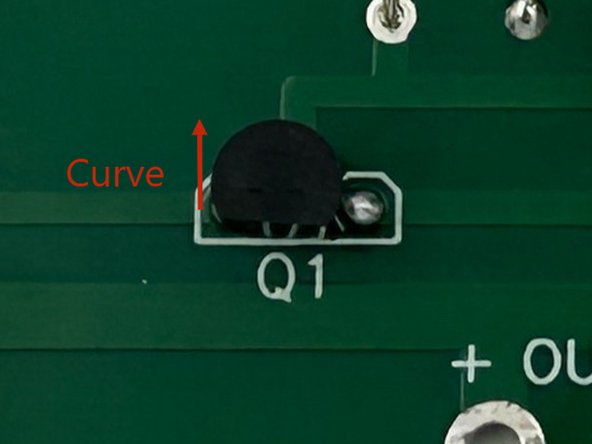

It is critical to orient the parts properly. Check the outline of the silkscreen and ensure the flat edge of the part matches the orientation of the flat side on the silkscreen and the bulged side matched the outline on the silkscreen. Check the photos if you are unsure.

-

Photo 1 - Q1 installed in the correct orientation.

-

Photo 2 - Note the direction.

-

Note - You may choose to install your JFETs raised above the boards as high as practical. This will allow you to potentially trim the leads and reuse them easily in another project.

-

Install Q1 for both boards. Q1 is the part marked K170.

-

-

-

It is critical to orient the parts properly. Check the outline of the silkscreen and ensure the flat edge of the part matches the orientation of the flat side on the silkscreen and the bulged side matched the outline on the silkscreen. Check the photos if you are unsure.

-

Photo 1 - Q2 installed in the correct orientation.

-

Photo 2 - Note the direction.

-

Note - You may choose to install your JFETs raised above the boards as high as practical. This will allow you to potentially trim the leads and reuse them easily in another project.

-

Install Q2 for both boards. Q2 is the part marked J74.

-

-

-

By this point, if you haven't already, take a break and triple check your work.

-

Wise and careful builders will have noted that each and every part has been verified, installed, and inspected.

-

This is also a perfect time to clean the back of the boards if you haven't been meticulously cleaning each joint as part of your inspection process. If you're using most popular solders, the boards don't strictly require cleaning, but it is much easier to inspect the joints if they're clean. Plus, it looks nice.

-

Note - 99%+ Isopropyl Alcohol and an old toothbrush were used to clean the boards; nothing aggressive or toxic.

-

Photo 1 - Dirty

-

Photo 2 - Clean. It may look like there is still a bit of residue due to the lighting / reflections in the photo.

-

-

-

These recommendations are applicable only with recommended parts. DIYers pursuing dual mono builds and/or using different power supplies or transformers should be confident in their ability to choose proper wiring and/or consult an expert.

-

AC Mains, DC Supply, and Speaker Wiring - 18AWG or larger.

-

Input - 20 to 30 AWG. Copper or Silver. Twisted pair or shielded coax. Solid Core or Stranded. These are all excellent choices, and are the choice of the builder.

-

-

-

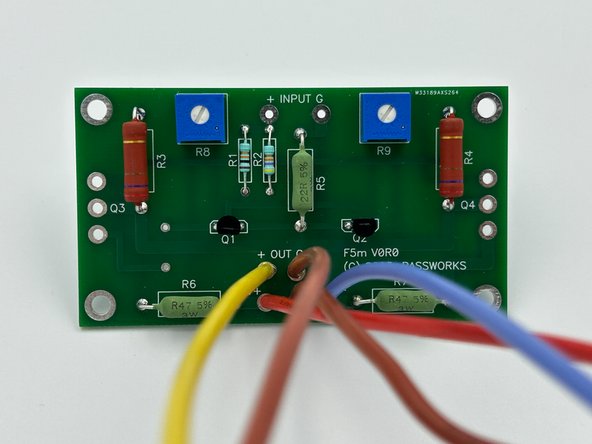

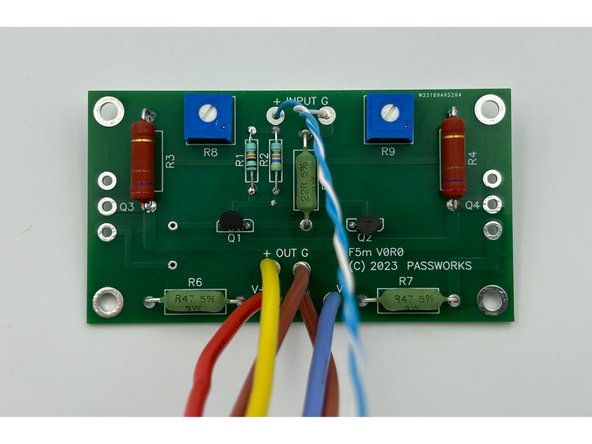

Choose your wire types and colors. It is wise to choose and use consistent colors that you can remember across your many future builds, particularly for power wiring. This example uses:

-

16 AWG multistrand:

-

Red for V+

-

Blue for V-

-

Brown for G and OUT G

-

Yellow for OUT+

-

Repurposed CAT6 for Input + and Input G

-

-

-

Cut your wires roughly to length and solder them to the amp PCBs. Err on the side of caution for wire length, and remember the wires will be twisted. Wire stretchers do not work well.

-

Photo 1 - 16AWG DC supply and output wiring installed.

-

Photo 2 - Input wiring Installed. If you are using repurposed CAT6 or similar for your input wiring, it is a good practice to use striped wire for GND.

-

-

-

The examples provided show:

-

2U heatsinks pre-drilled for the Universal Mounting Specification (UMS) pattern included with the Deluxe 2U chassis.

-

Electrically insulating thermal pads provided with the supplemental parts kit.

-

Board Mounting and MOSFET mounting hardware included in the supplemental parts kit.

-

-

-

As mentioned, this build uses the Deluxe 2U chassis. It is very similar for all Deluxe chassis with the pre-drilled and tapped UMS pattern.

-

If this is the first time you are using your heatsinks, ensure all tapped holes are free from burrs. You can use a finger tip to check. If there are burrs present, a piece of very fine wet sand paper, a fine file, or even a piece of green "Scotch Brite" pad will likely remove them. Be careful that you don't gouge the sink or damage the threads.

-

Make certain that you have the heatsinks properly aligned before assembly. Ensure that the two ends with shortest distance from the holes to the edges are joined at the middle. See photos.

-

Photo 1 - Two heatsinks, 8 screws, and the bracket. Note the alignment of the holes and the spacing in the middle vs. at the edges.

-

Photo 2 - Two proper heatsink assemblies.

-

Assemble both sets of heastinks.

-

-

-

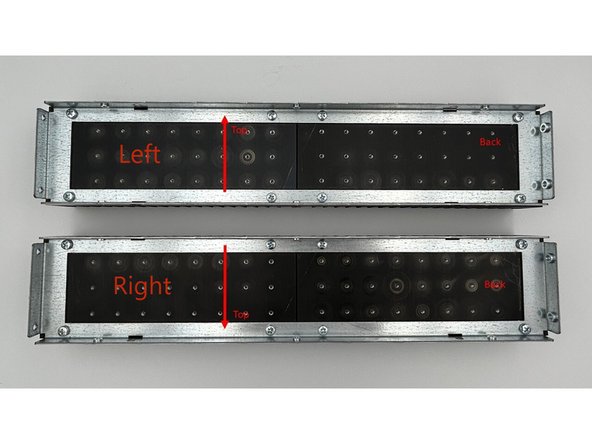

The heatsinks have a back and front. Once you choose left and right, they now have a top and bottom. It is generally preferred to have the input toward the top and the output toward the bottom of the chassis. It makes getting to the pots for adjustments much easier. The threaded holes in the brackets are for mounting the back panel.

-

Photo 1 - Heatsink orientation.

-

Place a PCB on the heatsink in the center. It should be quickly evident that the four mounting holes in the PCB easily line up with the holes on the heatsink (YAY UMS!). If they don't line up perfectly, triple check your work.

-

Noting where your boards and MOSFETs will mount, ensure each hole is free from debris. Gently ensure that an M3 screw will easily thread into the holes. If the screw binds, do not force it. Gently back it out, and start again. Do this until you can easily thread an M3 bolt for each hole.

-

Using the 8 spacers and 8 of the M3 bolts included in the supplemental kit, mount your amplifier boards to the heatsinks.

-

DO NOT over-tighten the bolts. Overtightening will can result in stripping the threads in your heatsinks, and you will be VERY sad. Firmly finger-tight is perfect. If the threads stick, back it in and out. A little lubricant may help also.

-

Photo 2 - Amplifier boards mounted to the heatsinks. Note the orientation.

-

-

-

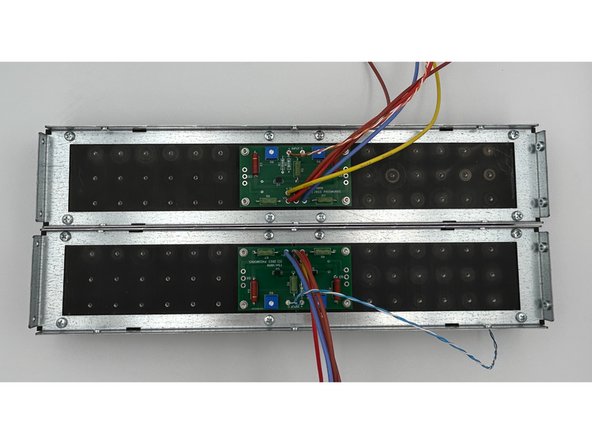

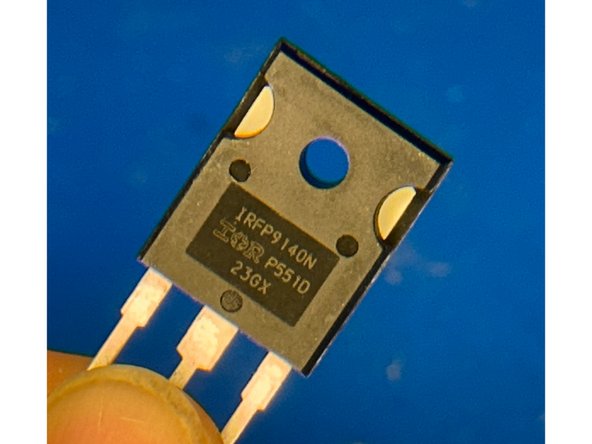

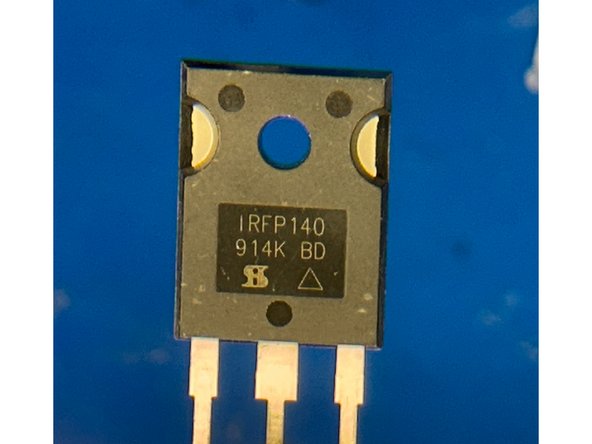

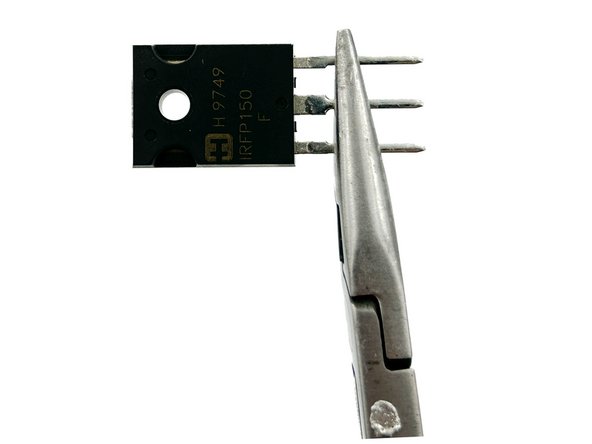

Your kit comes with 2 types of MOSFETs (4 Parts Total). They may look similar to the naked eye. It is critical to validate each part. Best practice is to check the case marking and measure the part. However, a visual confirmation is acceptable.

-

Use appropriate magnification to separate the 2 x IRFP9140 from the 2 x IRFP140.

-

Photo 1 - IRFP9140

-

Photo 2 - IRFP140

-

Note - The MOSFETs in your kit may differ in appearance from those in the photos.

-

-

-

Photos 1, 2, and 3 - It is simple to get a proper bend in the MOSFET legs, but care must be taken. These photos illustrate a proper sequence. The part is held just below the narrowing point in the legs, and the legs are bent to 90 degrees.

-

Note - The MOSFETs pictured are not those in your kit. This is only to demonstrate procedure.

-

Ensure that the lettering is up and the metal tab is down. You will bend toward the lettering. It is easy to adjust the angle slightly, but bending them back in the entire opposite direction may result in premature failure due to metal fatigue.

-

Bend all three leads of your MOSFETs to a 90 degree angle as shown. They don't need to be perfectly 90 degrees. Just get it close.

-

-

-

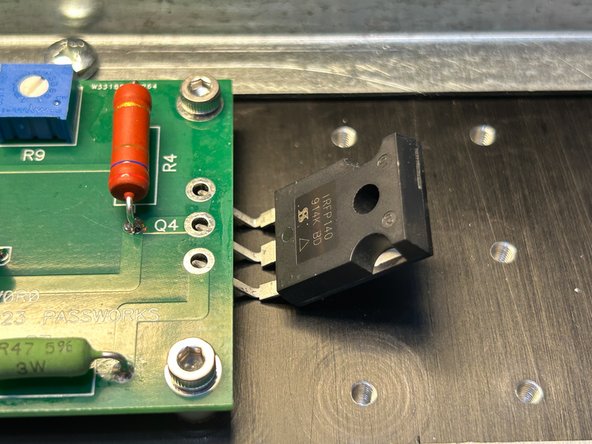

Angle the MOSFETs, and gently slide the MOSFET legs into the holes on the amp boards. They should just fit if you've bent the legs to 90 degrees. If not, you can slightly loosen the PCB mounting bolts and/or adjust the bend in the legs slightly.

-

Photo 1 - Angle the MOSFETs and gently slide the legs into the holes.

-

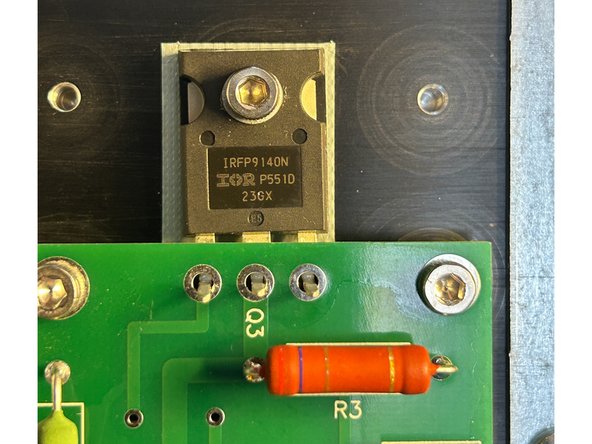

Quadruple check that the IRFP9140s are in the spots for Q3 and the IRFP140s are in the spots for Q4.

-

Gently slide an insulating pad (included with the supplementary kit) under each MOSFET.

-

Photo 2 - Place the Belleville washers onto the M3 bolts. Note the orientation.

-

For each MOSFET - Align the MOSFET hole, the insulator hole, and the heatsink hole. Good lighting helps. Ensure that each insulator FULLY extends beyond all edges of the MOSFET.

-

Fasten all the MOSFETs to the heatsinks using the M3 bolts and Belleville washers. Compress the Belleville washers. You should be able to feel when they're fully tightened. There's no need to overly tighten them. If you happen to have a torque wrench, the spec is 1.1 Nm.

-

Photo 3 - Note how the insulator properly extends beyond the edges of the MOSFET. This is critical.

-

-

-

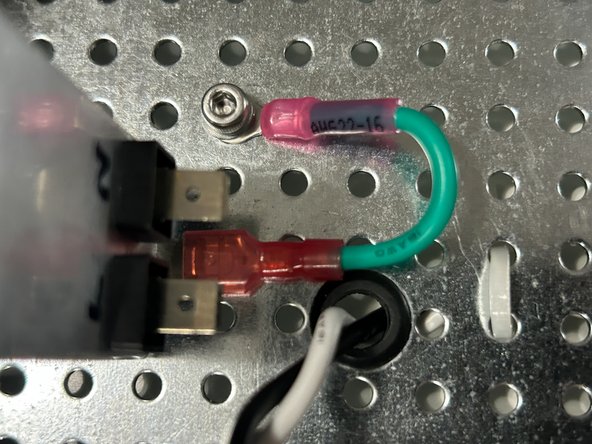

It is critical to check the resistance from the heatsink (chassis / mains earth) to each pin of the MOSFETs prior to soldering them into place. The metal back of the MOSFET is the drain, and it must be electrically isolated from the heatsink.

-

Check the resistance between the two bolts mounting the MOSFETs. It should be less than a few Ohms. If not, DO NOT proceed.

-

Photo 1 - Meter set to resistance. Probes placed between MOSFET mounting screws.

-

Note - You are measuring to ensure that the two heatsink sections are connected electrically to what will be established as "chassis ground" / Mains Earth. This is critical to safety.

-

Check the resistance from all 3 of the legs for both MOSFETs to the head of the screw mounting the MOSFET.

-

If the reading is not O.L (over limit) or in the MOhm range, check that your insulating pads are covering the entire base of the MOSFETs. DO NOT proceed if you do not measure in the MOhm range or your meter does not read O.L. (over limit).

-

Photo 2 - Meter set to resistance. Probes placed on mounting screw (mains earth / chassis GND) and pin 2 (drain). O.L (A very high resistance) is a proper result.

-

-

-

One more time with feeling. MAKE SURE that the MOSFETs are in the correct locations. Q3 - IRFP9140 and Q4 - IRFP140.

-

The solder joints for the MOSFETs are exposed to thermal stresses over the long life of a properly built amplifier. It is important to ensure good solder flow and a proper joint. The thermal mass / area of the joint is relatively large. The use of flux and/or a slightly higher soldering temperature or larger tip is recommended.

-

Solder the three pins of each MOSFET to the amp PCBs.

-

Photo 1 - If you've been checking off your parts on the schematic as they're verified / installed / inspected; it may look like this.

-

Photo 2 - Two fully assembled amplifier boards on their heatsinks. Note that the MOSFETs aren't perfectly aligned; it is not a concern.

-

Double check the resistance measurements from Step 28. It's rare, but things can shift. It takes <30s, and it's critical; so why not?

-

Set your amp board heatsink assemblies aside for now.

-

-

-

You've now completed your amplifier boards and done an initial check to ensure that they mount without issue. It's a perfect time to congratulate yourself and take a break.

-

-

-

This is an example build of a linear power supply designed for, and appropriate for, the F5M. If you are not using these exact components, it is critical that you, the builder, verify each and every component and the circuit for suitability.

-

This example will demonstrate the wiring for 110/120VAC mains using an Antek AS2218 transformer. In the future, a wiring diagram for 220/240VAC may be added. As mentioned, the AS-2218 is being used due to the height restrictions of the 2U chassis. In addition, the 200VA transformer is more than sufficient for a low bias build.

-

Building this power supply includes wiring mains AC. Exposure to mains AC can be lethal. It is critical to follow proper safety procedures. If you are unsure how to proceed, seek qualified assistance.

-

-

-

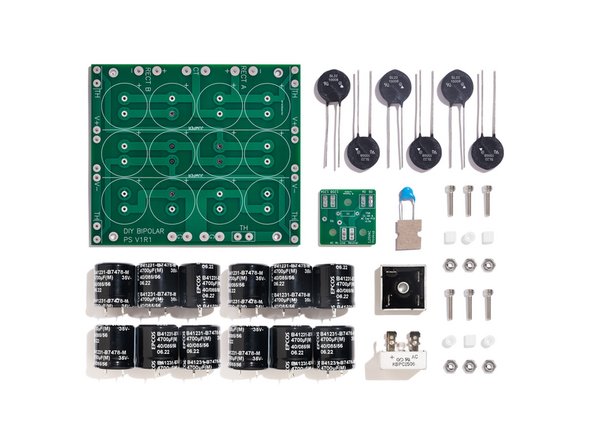

Carefully empty the contents of your PSU Kit onto your work surface or into a bowl. Double check the contents of your kit. The spacers are small and will wander. Keep track of them!

-

Photo 1 - PSU Kit Bag - This build incorporates PSU V1R1. If you do not have V1R1, and if you are unsure, please consult an expert and/or your friends in the forum for slight differences.

-

Photo 2 - Kit Contents

-

-

-

You'll need to make a few decisions for your build that include, but are not limited to:

-

Are you willing to drill/enlarge a few extra holes in your perforated baseplate? You'll need to enlarge one hole to mount the transformer. This build required enlarging two more holes.

-

Do you prefer the trade-off of ease of assembly for the purchase of a few extra parts? This build uses connectors that are commonly available and not comparatively expensive to connect essential sections of the power supply and mains wiring.

-

If you have a chassis with enough height, do you want to mount your transformer vertically? The chassis in this build is a 2U. A photo of a 4U chassis is provided for reference and inspiration.

-

Most importantly, these are examples. Make your build your own. If you follow a few general principles, your amplifier will have very low noise, and it will be much simpler to assemble.

-

-

-

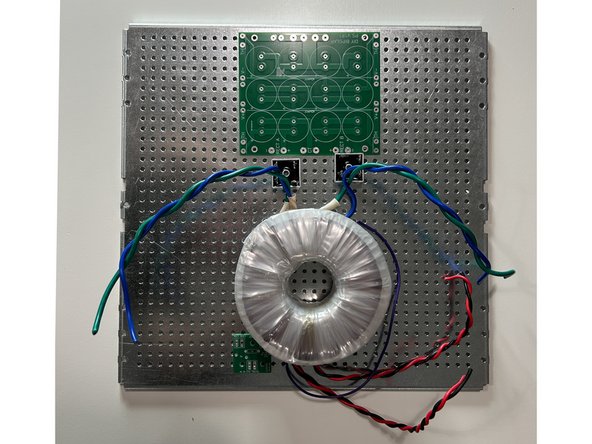

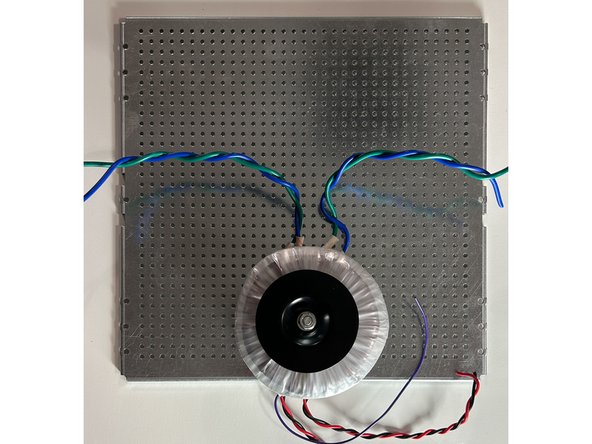

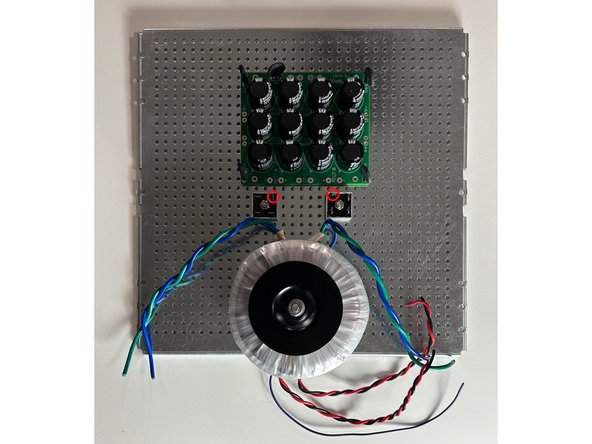

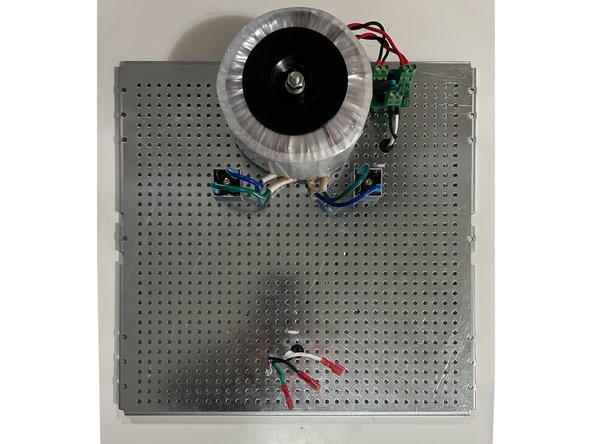

Gather the perforated base plate, the power supply PCBs, the rectifiers, and your transformer. Begin to plan your chassis layout keeping in mind wire routing that may include, but is not limited to:

-

AC Power Wiring - Mains Live, Neutral, and Earth; Transformer Primaries; and Transformer Secondaries. The overall idea is to use practical methods to keep the AC wiring away from your signal wiring. In this build, the mains AC Live and Neutral will be routed under the perforated baseplate.

-

Transformer placement - transformers radiate energy that can be picked up in the audio circuit. A good location for the transformer is at the front of the chassis in the center.

-

Signal Wiring - Input and Speaker - The main idea is to keep the wiring as short as practical and away from the AC mains and transformer wiring.

-

DC Power Wiring - V+, V-, and GND - The main idea is to keep the wiring as short as practical.

-

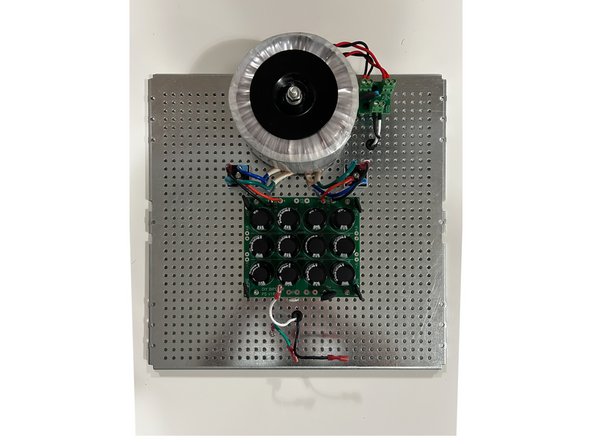

Photo 1 - An initial rough layout for this build.

-

Photo 2 - A complete build by 6L6 in a 4U chassis. The taller chassis will allow the transformer to be mounted vertically. Take note that where the AC mains wiring crosses the DC supply wiring it does so at almost a perfect right angle. There are 100s of ways to lay out a project.

-

-

-

It is good practice to print a schematic for every circuit and tick off components as they are installed, but this board only has two different components. It would be a challenge to install them in the wrong locations.

-

Install the thermistors.

-

Photo 1 - Thermistors installed.

-

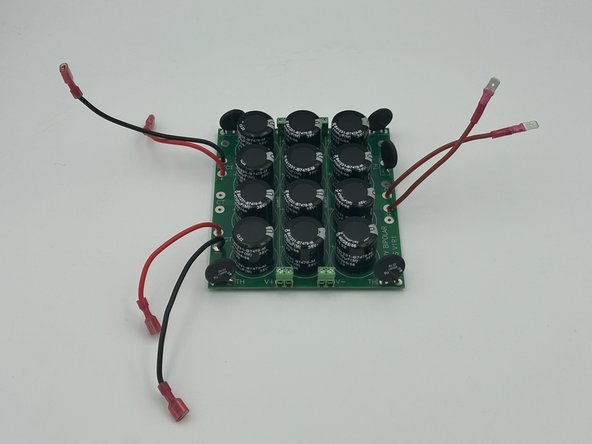

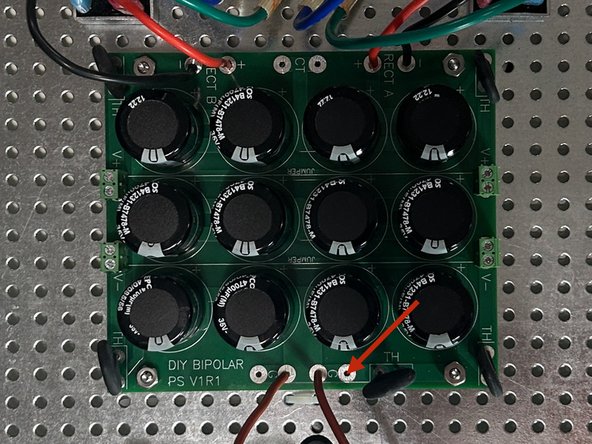

Install the 12 filter caps. The band on the capacitors indicates the negative side. Ensure that the band is on the opposite side of the (+) on the PCB silkscreen.

-

Note - It is not necessary to trim the leads on the snap-in caps.

-

Photo 2 - Caps Installed. Note the direction of the bands.

-

Clean the back of your board if you'd like.

-

Photo 3 - Back of the board.

-

-

-

There are quite a number of ways to connect the PSU filter board to the rectifiers, to the amplifier boards, and even to the speaker binding posts (if that's your choice).

-

The goal for this build was secure, easy-to-assemble, common connection types . It is a nice feature to allow for a simple connection / disconnection of the amplifier boards and rectifiers for testing and troubleshooting. Your choices may differ. This build incorporates:

-

Terminal blocks for the V+ and V- connections to the amplifier boards.

-

Spade connections for the GND connection to the amplifier boards. The speaker ground will connect from the amplifier boards to the speaker binding posts.

-

Photo 1 - All connections / terminations set on the amplifier boards.

-

If you're unsure of any connections, please seek assistance.

-

Finalize your plan for making your PSU connections and add any necessary terminations.

-

-

-

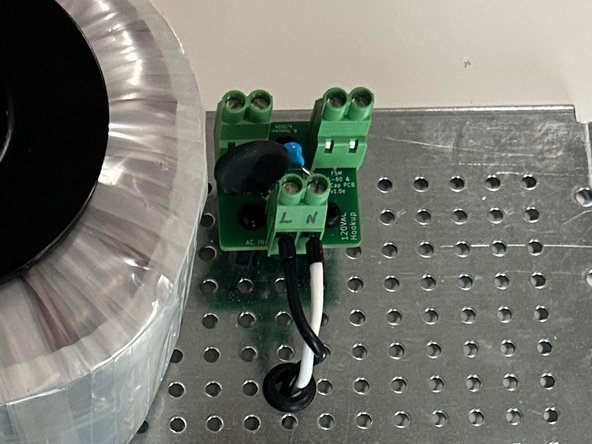

There are a few options for mains hookup. This build uses a connection that can be removed as needed for ease of assembly and testing; Phoenix part number 1714955. They are more than sufficient with a 32A, 640V rating. Why were these massive parts chosen? They were in the drawer. A DIYer improvises.

-

To use terminal blocks like this successfully with stranded wire, bootlace ferrules are an acceptable option. You can buy a tool and 1,000s of ferrules on many popular websites. Ensure that the crimp is proper to ensure the wire cannot be removed from the ferrule without using unreasonable force.

-

Other options include, but are not limited to soldering the wires directly to the PCB or using blade / "Fast-On" connectors.

-

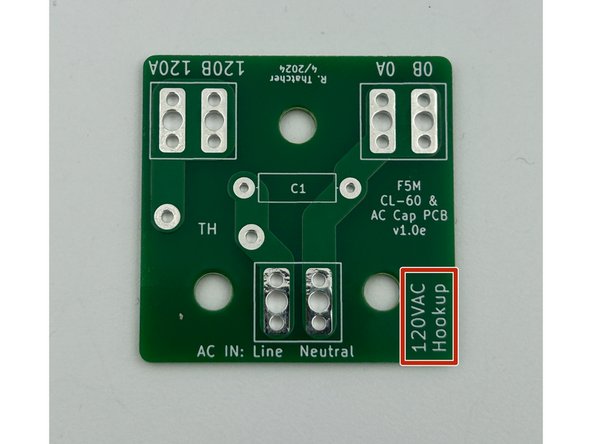

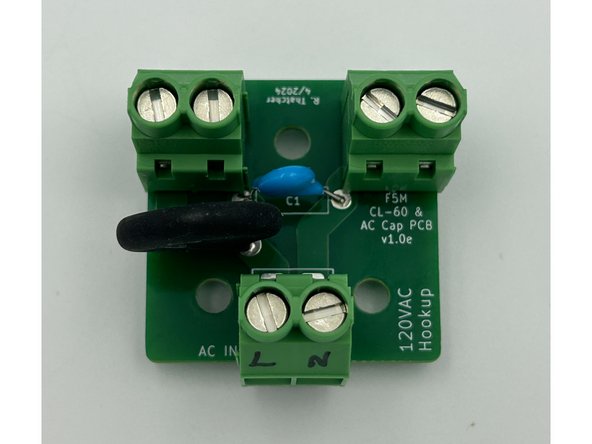

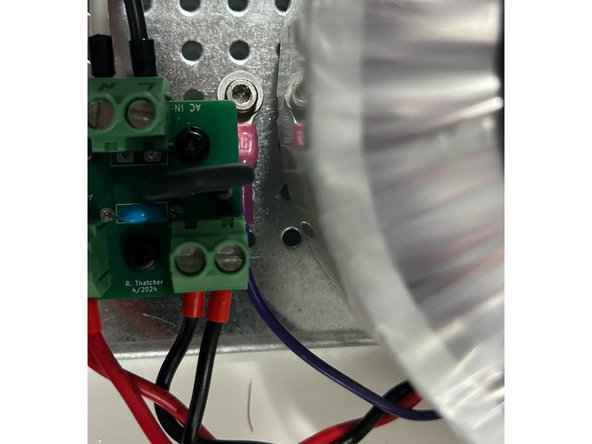

Photo 1 - This build is for 120VAC Mains. All components will be installed on this side of the board.

-

Install the safety cap, the thermistor, and your choice of connectors (as applicable).

-

Photo 2 - One example of a completed Mains AC Hookup board. The Line and Neutral (L and N) are labeled on the terminal block since the silkscreen was obscured. It is not strictly necessary, but it is a best practice to differentiate line and neutral AC mains wiring even within sealed electronics.

-

-

-

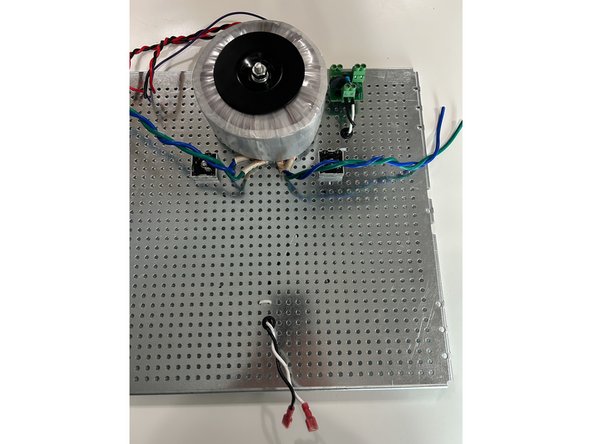

The order you mount the boards / components is somewhat arbitrary, but it is a good practice to start with the transformer simply due to the size.

-

Find and mark a mounting hole that keeps the transformer centered (roughly centered is fine) left to right and close to the front of the chassis.

-

Drill / Enlarge the hole for the transformer mounting bolt.

-

Photo 1 - Mounting position for this build.

-

Mount the transformer. The order is - Bolt (through the base plate), rubber mount, transformer, rubber mount, metal top plate, washer, split washer, then nut.

-

You can keep the bolt a bit loose for now, so it can be rotated into final position later.

-

At this point, particularly with a 2U chassis, briefly mount the heatsinks to the perforated base plate (or simply place them) to double check that you have proper clearance between the transformer plate / bolt assembly and the top panel. The transformer mounting bolt MUST NOT make contact with the top panel.

-

Photo 2 - Transformer mounted. (Don't worry about the twisted wires. This transformer was borrowed from another project.)

-

-

-

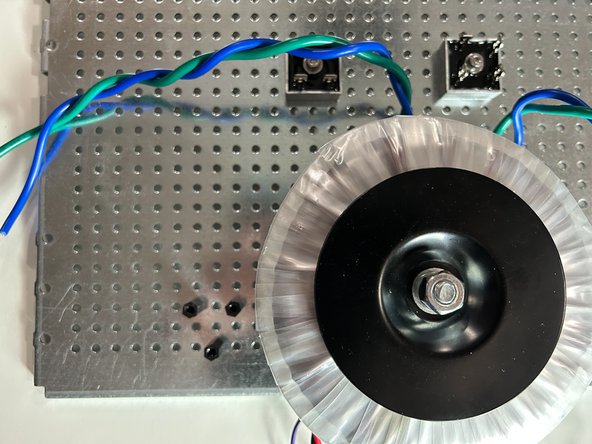

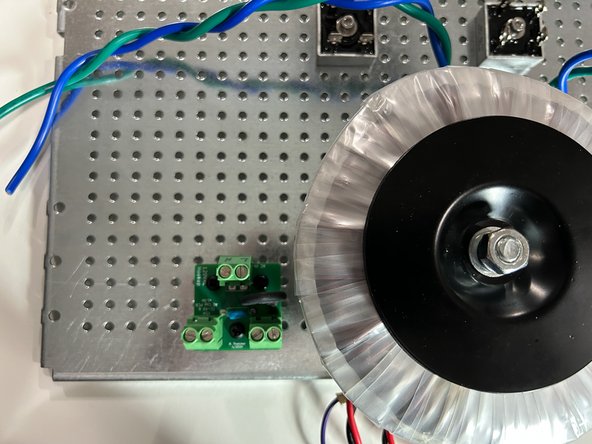

You'll need some hardware not included in your kit to mount the rectifiers. M4 x 20 bolts, washers, and split washers work well for mounting. Use whatever is convenient.

-

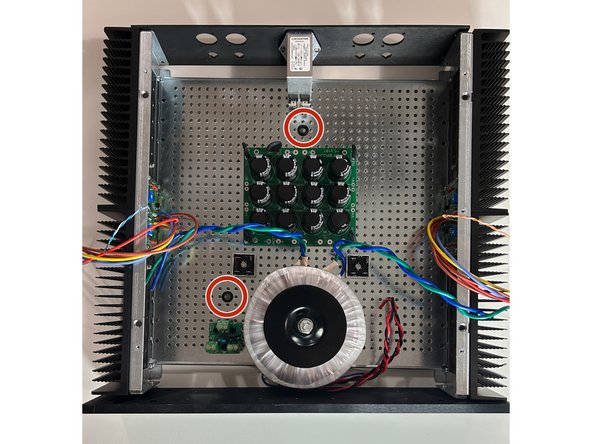

Choose a placement for the rectifiers using the transformer and the main PSU PCB as a reference. The rectifiers connect from the transformer to the PCB. Note the pin on the rectifiers that is oriented differently (circled in red in photo 1). That pin is the DC+ output and can be placed close to the RECT+ pad for shorter wiring.

-

The rectifiers will get warm / hot. The perforated baseplate acts as a heatsink. So, mount them tightly, but don't over tighten. Once again, split washers are recommended to keep the rectifiers securely mounted over many thermal cycles.

-

Photo 1 - This layout leaves enough space, to not have cramped wiring with the transformer. There is plenty of space in this chassis. Leaving extra room makes builds easier. Note: the main PSU PCB is not mounted. It is shown for placement only.

-

Briefly review step 44 to see a few potential improvements in rectifier placement from photo 1.

-

Mount the rectifiers in your preferred locations.

-

-

-

Make sure the Mains AC Hookup board is raised above the perforated base plate by at least a few millimeters. Leads / traces / pads on the PCB MUST have appropriate clearance above the perforated base plate.

-

Mount your Mains AC Hookup board to your perforated base plate using the nuts, bolts and nylon spacers included in your kit. Adding a split washer is advised. It is critical that no wire-ends or leads make contact with the perforated baseplate.

-

Photo 1 - This is a good location. Remember, the mains wiring for this example runs under the perforated base plate. Your mounting choice may be different.

-

Note - At the time of writing, the author did not have the spacers included with the kit. Nylon M4 standoffs were chosen as a substitute. Again, DIYers improvise.

-

Photo 2 - AC Hookup Board mounted.

-

-

-

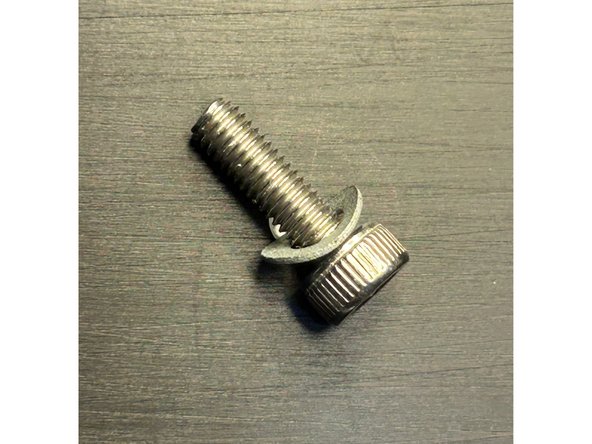

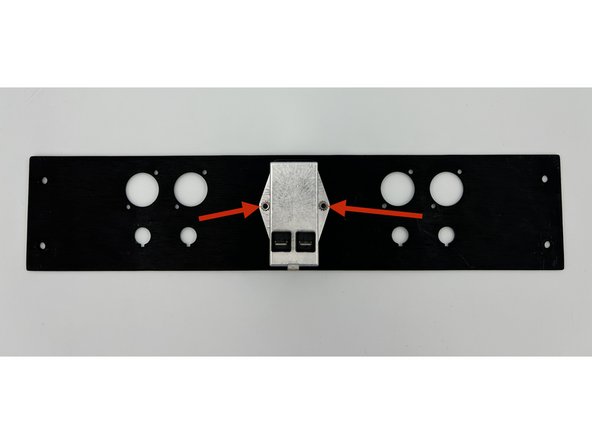

The Power Entry Module (PEM) mounts from the inside of the chassis using 2 black M3 cap head screws and Keps nuts included in the back panel parts kit.

-

Remove the PEM from the back panel parts kit and mount it to the back panel.

-

Photo 1 - Properly mounted PEM using black M3 bolts and Keps nuts from the back panel parts kit.

-

Photo 2 - External view.

-

-

-

Place the back panel, front panel, and heatsinks around the baseplate to ensure clearances. There's no need to bolt anything into place at the moment. Place the PSU PCB onto the baseplate. Visualize the wire routing.

-

Note - During evaluation of the layout, it was noticed that moving the PSU more toward the middle of the chassis would allow additional clearance around the PEM and shorter DC wiring between the PSU and the amplifier boards. The rectifiers were relocated from Step 41 to adjust.

-

Photo 1 - Final layout for AC. Keen-eyed observers will note two holes (circled in red) for routing the mains AC wiring under the perforated baseplate.

-

If you choose to route your AC wiring under the perforate baseplate / through the holes, you MUST protect the mains wiring from potential nicks / cuts from the metal plate. In this build, common rubber grommets were used.

-

-

-

It is convention in the USA to use black for the AC Line / Hot / Live wiring and white for the AC Neutral wiring. This example uses 16AWG stranded wire rated for 600V.

-

It is solely your responsibility to follow all proper regulations and codes for electronic projects in your country / area.

-

Prepare enough twisted pair of your mains wire to comfortably go from the PEM to your AC Hookup board. Err toward having extra wire.

-

Many people use a cordless drill to twist their wiring.

-

Choose your appropriate wire routing and terminate the wires on the PEM end appropriately. This build used commonly available, appropriately-sized, and appropriately crimped female blade connectors.

-

Photo 1 - Mains wiring (black and white wires) routed below the perforated base-plate. The zip-ties are holding the wiring loosely in place.

-

Photo 2 - Mains wires terminated properly for PEM connection.

-

-

-

Using the PEM on the back plate as a rough guide for length. Cut the mains wiring to length at the Mains AC Hook Up board.

-

Leaving the wire a little long is preferable. You can take up a small amount of slack when you tighten the zip-ties and add an additional zip-tie to secure the wiring.

-

Connect the Black Wire to the board at the pad marked Live. Connect the White Wire to the board at the pad marked Neutral.

-

As mentioned, this build uses terminal blocks along with bootlace ferrules for the connections.

-

Photo 1 - Mains wiring routed.

-

Photo 2 - Mains wiring connected to Mains AC Hookup Board.

-

-

-

It is convention in the USA to use Green or Green / Yellow stripe wiring for mains safety earth connections. This build uses Green 16AWG stranded wire rated for 600V. You will need hardware not included in your kits for securing the mains earth connection to the perforated base plate. An M4 bolt, M4 nut, and a split washer may be used.

-

The mains safety earth connection is critical. Ensure that you are following all your country / local area regulations and guidance for mains wiring.

-

As a general rule, the mains safety earth wire should be short, robust, and make a very secure connection / have a very low impedance to any exposed conductive surface an end-user may make contact with.

-

Cut a short length of wire, terminate it appropriately for your PEM, and install it onto the PEM ground connector.

-

Photo 1 - Use of the PEM and backplate to estimate wire length.

-

Identify the hole (or area) in the baseplate to which you will connect the safety earth wire. Securely mount the mains safety earth wire to the perforated baseplate.

-

Photo 2 - Mains safety earth securely connected to the PEM and the perforated base plate.

-

If you chose to direct solder the safety earth wire to your PEM, the order of operations may be different in your build. It is up to the builder to choose the sequence and terminations / connections meeting their electrical and safety standards.

-

-

-

All the recommended Antek transformers are dual primary. You need to separate and identify the separate primary windings. Each primary has one end with red insulation and one end with black insulation.

-

DO NOT assume that the two red ends are one primary and that the two black ends are the other primary; you will be VERY sad.

-

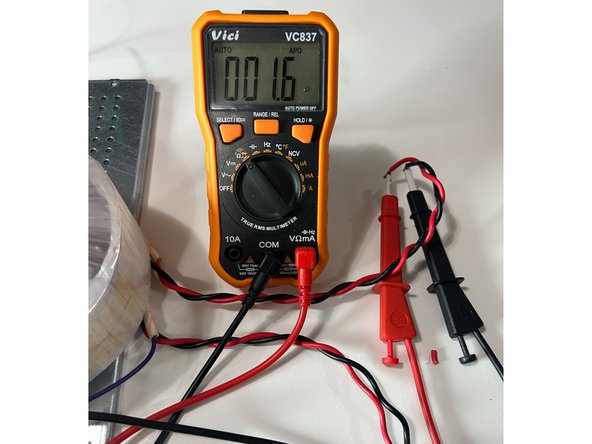

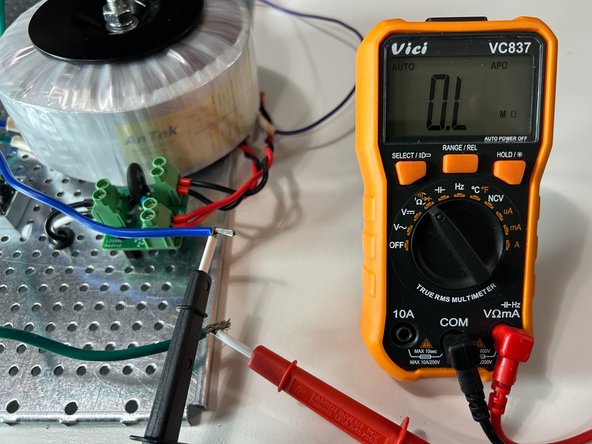

Using your DMM set to resistance, take one red wire and one black wire and measure the resistance. If the resistance is below 10 ohms, keep those two ends together and identify them. Otherwise, trade the two black ends, and measure again. Now, you should have a resistance below 10 ohms. Label one black/red pair A and one pair B.

-

Photo 1 - Example of two ends not matching. Note the resistance is over limit. These are not two ends of the same wire (primary winding).

-

Photo 2 - Example of two ends matching. Note the resistance is under 10 ohms. These are two ends of the same wire (primary winding).

-

You may chose to twist the matching red and black pairs together. It's not critical.

-

-

-

Note - Some people never cut their transformer wiring to length in order to ensure they can use them in multiple projects. It is your choice. Also, leaving the wires a little longer will allow you to rotate the toroid into the perfect position to minimize hum. This may be important in tighter builds and for those with sensitive speakers.

-

Cut the primary wires to length and terminate as appropriate.

-

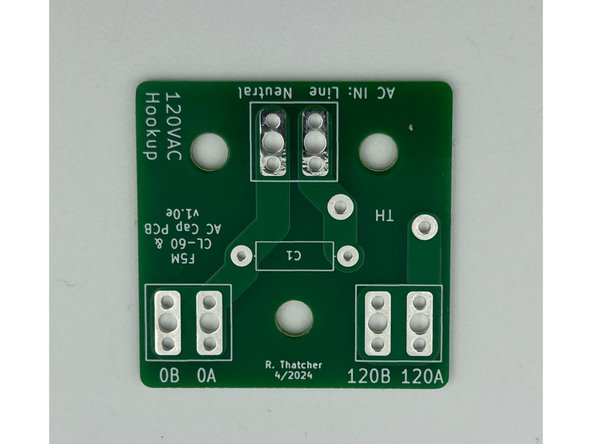

Photo 1 - Reminder of critical connection markings. Note - 0A, 0B, 120A, 120B, Line, and Neutral.

-

Connect the red end of the primary you have labeled A to the board at the point marked "0A".

-

Connect the black end of the primary you have labeled A to the board at the point marked "120A".

-

Connect the red end of the primary you have labeled B to the board at the point marked "0B".

-

Connect the black end of the primary you have labeled A to the board at the point marked "120B".

-

Photo 2 - This is one example of the connections using terminal blocks and bootlace ferrules.

-

-

-

The recommended Antek transformers are dual secondary transformers. You now need to separate and identify the two secondary windings. Each secondary winding has one end with blue insulation and one end with green insulation.

-

DO NOT assume that the two green ends are one secondary and that the two blue ends are the other secondary; you will be VERY sad.

-

Using your DMM set to resistance, take one green wire and one blue wire and measure the resistance. If the resistance is below 10 Ohms, keep those two ends together and identify them. Otherwise, trade the two blue ends, and measure again. Now, you should have a resistance below 10 Ohms. Label one blue/green pair A and one pair B.

-

Photo 1 - Example of two ends not matching. Note the resistance is over limit. These are not two ends of the same wire (secondary winding).

-

Photo 2 - Example of two ends matching. Note the resistance is under 10 Ohms. These are two ends of the same wire (secondary winding).

-

You may choose to twist the matching green and blue pairs together. It's not critical.

-

-

-

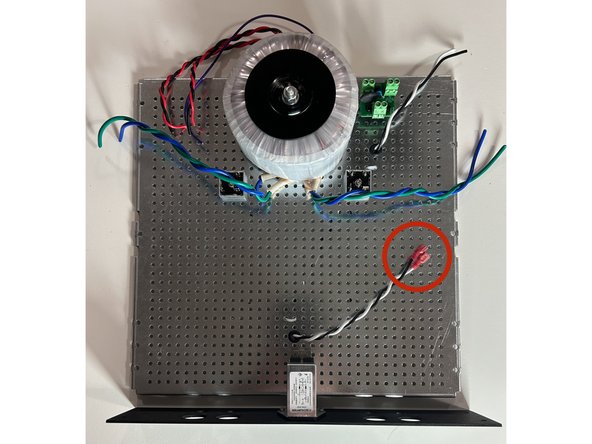

Antek AS transformers have a magnetic shield that must be connected to mains earth. It is best to leave this wiring as short as practical, but many people do not like to cut their transformer wires to ensure they can use it in future projects. The decision is up to the builder. It is not critical.

-

Cut the purple shield wire to length as appropriate. Terminate it for connection to the perforated base plate. This build uses a common ring connection.

-

Securely fasten the shield wire to the perforated base plate.

-

Photo 1 - One example of the attachment location and method.

-

-

-

Photo 1 - READ THIS!

-

It is absolutely critical that you exercise safe practices when working with any mains powered device. At this point of assembly, all wiring at mains voltage potential MUST be properly insulated from exposure, and safety mains earth must be connected to any conductive surface. This includes, but is not limited to:

-

Ensure that the termination chosen for the mains live, neutral, and mains safety earth wiring connected to the PEM are properly insulated.

-

Ensure that the terminations / connection from the live / neutral wiring to the Mains AC Hookup board are properly insulated and/or that the potential for incidental contact with mains wiring is minimized.

-

Ensure that your safety mains earth connection is properly insulated at the PEM and is securely connected to your perforated base plate.

-

Ensure that ALL mains wiring insulation is fully intact and that it is protected from any sharp edges.

-

-

-

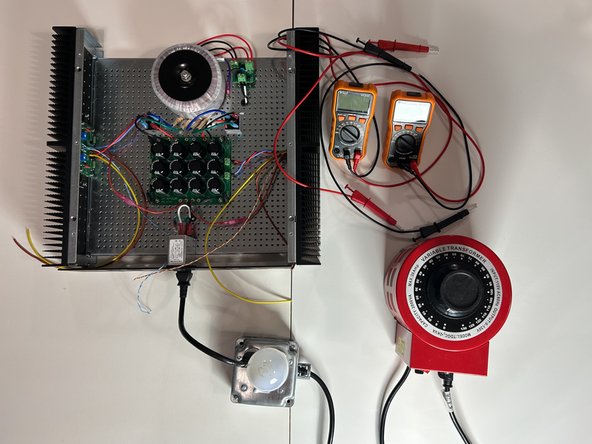

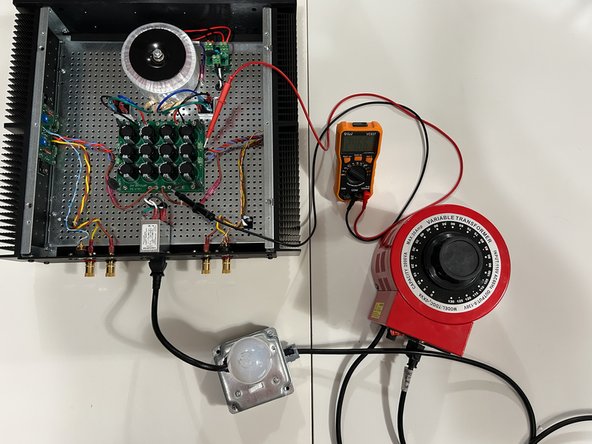

It is highly advised to do the following checks with a dim bulb tester (DBT) or some means of current limiting and/or a variable transformer. If you are unfamiliar with the use of current limiting / voltage limiting methods, please consult an expert.

-

Early checks of the PSU should not draw any significant current. You may choose to use a low amperage fuse in the PEM to further reduce the risk of damage to components in the event you have made an error in any previous steps. The PEM included in the back panel parts kit uses 5mm x 20mm fuses. A 0A5 (slow blow) or less would be appropriate.

-

If you've disconnected any of your mains wiring for ease of assembly, connect your mains wiring to the PEM. Place your perforated base plate / PSU assembly on a clean / neat / clutter free work space with a non-conductive surface.

-

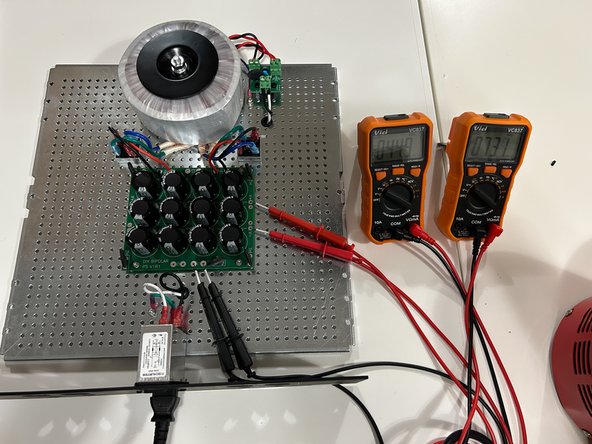

Connect a DMM set to ACV to each of the transformer secondaries. Ensure that the ends of the secondaries cannot touch each other or the perforated base plate (mains safety earth). Consider using electrical tape or other means to ensure none of the 4 secondary wires can accidentally contact each other or the baseplate.

-

Ensuring the power is off / disconnected, plug in your variable transformer / DBT (as applicable)

-

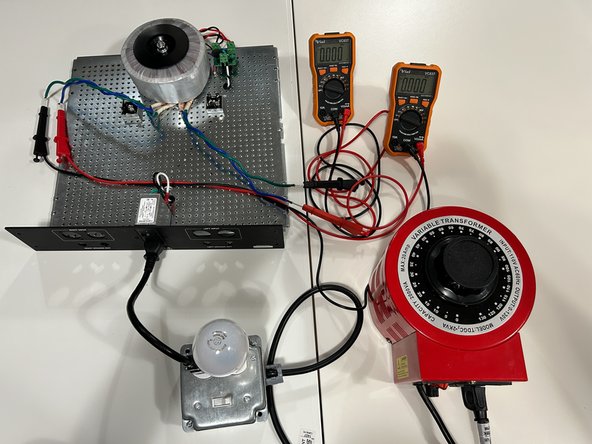

Photo 1 - Example of preparing for initial testing. DMMs set to ACV and connected to each secondary. Variable transformer and DBT are in place. Note - from this angle the photo doesn't show the intended separation of each end of the secondaries and the baseplate. It is important!

-

-

-

Double / Triple check all mains wiring. Turn the power switch off on the PEM.

-

Set the DMM to resistance. Check to ensure:

-

Very low resistance (less than one Ohm) from the PEM live and neutral to their corresponding connections on the Mains Hookup board.

-

Very low resistance (less than one ohm) from the mains safety earth pin on the PEM to the perforated base plate.

-

Very high resistance (O.L.) between Live tab on the PEM and the perforated baseplate.

-

Very high resistance (O.L.) between Neutral tab on the PEM and the baseplate.

-

Very high resistance (O.L.) between Neutral tab on the PEM and Line/Live tab on the PEM.

-

If ANY of these checks are not as expected, DO NOT PROCEED. Troubleshoot and/or seek assistance.

-

-

-

Prepare - place yourself in a position to quickly turn the power to the circuit on and off. Ensure you can see both DMMs. Immediately power off the circuit if you smell smoke, see sparks, if the DBT bulb glows brightly, or if there is any indication that things are not working properly.

-

Ensure (as applicable) the variable transformer is set to the lowest output. Power the circuit. If you're using a variable transformer, you'll see roughly the same voltage as when you connected the DMMs. If you're not using a variable transformer, you should see roughly 19VAC.

-

The DBT bulb should remain dim.

-

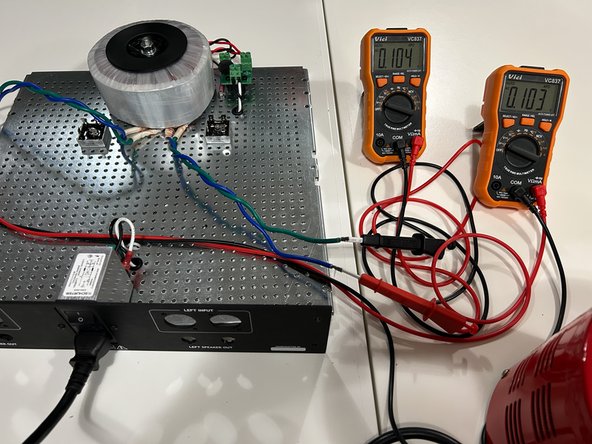

Photo 1 - In this example, since the variable transformer was set to a low output, there is very little voltage at the transformer secondaries. This is good.

-

If you are using a variable transformer, gradually increase the voltage to approximately your mains voltage. You should measure approximately 19VAC at the transformer secondaries.

-

The DBT bulb should remain dim.

-

Photo 2 - Looking Good.

-

Power down the circuit. Disconnect the DMMs and test gear.

-

-

-

Some people do not like cutting their transformer secondaries. This may allow them to be reused in a variety of future projects. The choice is yours. As with the primaries, leaving some extra length will allow you to rotate the transformer if necessary.

-

Cut the transformer secondaries to length and terminate appropriately. In this build, appropriately-sized and crimped female 'Fast-On' / blades were used.

-

NOTE THE MARKINGS ON THE RECTIFIERS AND THE ORIENTATION OF THE BLADES.

-

Photo 1 - The blade facing differently than the other three is the (+) DC output. The blade diagonal is the (-) DC output. The other two blades are for the AC connections.

-

Connect your transformer secondaries to the rectifiers.

-

Photo 2 - Secondaries connected. Note, in this example, the rectifiers are turned 90 degrees from each other to keep the DC wiring to the filter boards aligned (see Step 40)

-

-

-

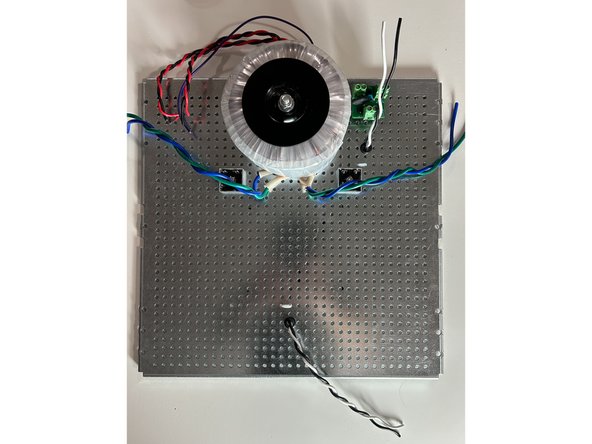

Depending on your previous choices for wiring / connections your steps may differ slightly. For this build, the main PSU board will be temporarily mounted for wiring and DC voltage testing. This build uses red for DC+ and black for DC- wiring between the rectifiers and the main PCB.

-

Place your main PSU board on the perforated base plate and choose what should be the final mounting position. Estimate the amount of wire needed to connect the (Rect +) and (Rect -) pads to the rectifiers. The side of the PSU PCB with pads for RECTA, RECT B, and CT should face the rectifiers.

-

Cut two lengths of wire for the positive connections and two lengths of wire for the negative connections and solder them to the Main PSU PCB.

-

Mount the PCB to the perforated baseplate using the spacers, bolts, and nuts provided. It is appropriate, but not strictly necessary to add a split washer. The circuit requires a proper electrical connection to the perforated base plate (mains earth) through the mounting bolts. If the mounts loosen over time, it could result in failure.

-

Cut the wires to length, terminate accordingly, and connect the wiring to the rectifiers. In this build, appropriately sized and crimped 'Fast-On / Blade type' connectors were used.

-

Ensure you have proper electrical connection to the perforated base plate. Measure the resistance from the ground pad on the PCB to the perforated base plate. It should be around 10 Ohms. The thermistor is acting as a "ground lift". See photo 2.

-

Photo 1 - Main PSU PCB mounted (temporarily). Rectifiers connected to PSU PCB. Note the position of the (RECT+ and RECT- pads to the rectifiers.

-

Photo 2 - Measure the resistance between the ground pad and the perforated baseplate. It should be roughly 10 Ohms.

-

-

-

In the event of a failure, venting capacitors will almost certainly startle you and could cause serious injury. Safety glasses are advised.

-

-

-

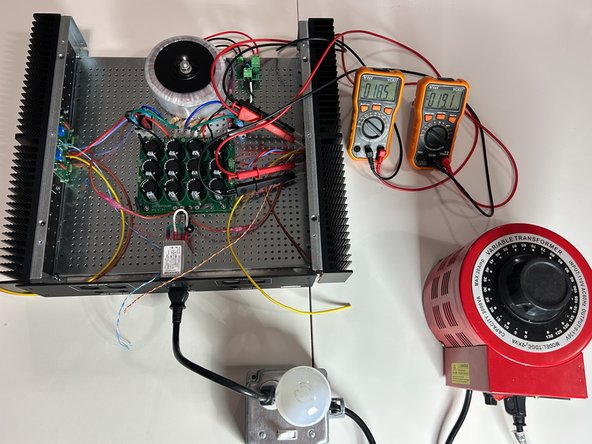

It is highly advised to do the following checks with a DBT or some means of current limiting and/or a variable transformer. If you are unfamiliar with the use of current limiting / voltage limiting methods, please consult an expert.

-

If you've disconnected any of your mains wiring for ease of assembly, connect your mains wiring to the PEM. Place your perforated base plate / PSU assembly on a clean / neat / clutter free work space with a non-conductive surface.

-

Ensuring the power is off / disconnected, plug in your variable transformer / DBT (as applicable)

-

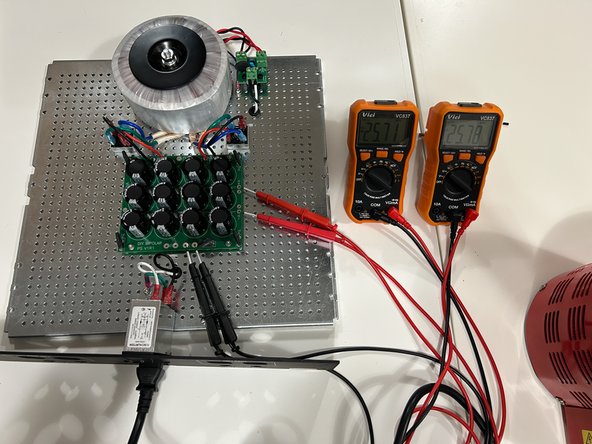

Photo 1 - Example of PSU prepared for testing.

-

Start with the left channel PSU. Set your DMMs to DCV. Connect the black probes of each DMM to a G pad (Ground). Connect the red probe of one DMM to the V+ pad. Connect the red probe of the other DMM to the V- pad.

-

Photo 2 - Probes connected. Note - there is no concern if you measure a small voltage. This example is in the mV range and is perfectly normal. If you're connecting your probes again after a recent power up, you may see up to the full rail voltage. There is no load on the PSU, and there are no bleeder resistors in this design.

-

It is recommended to bleed / discharge the capacitors to below 2V. If you are unsure how to do this, consult an expert.

-

-

-

Ensure (as applicable) the variable transformer is set to the lowest output.

-

Ensure you can see both DMMs. Immediately power off the circuit if you smell smoke, see sparks, if the DBT bulb continues to glow brightly after initial power up, or if there is any indication that things are not working properly.

-

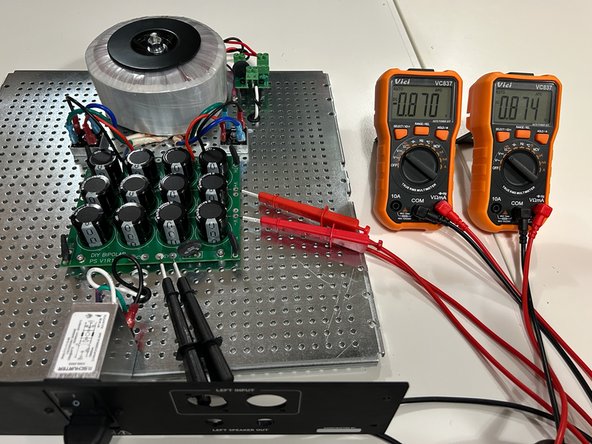

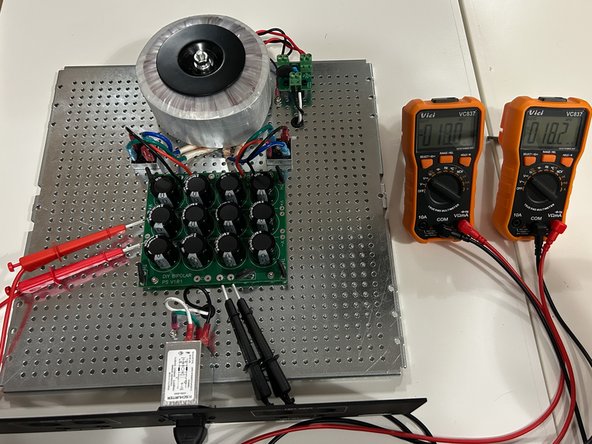

Power the circuit. If you're using a variable transformer, you'll measure roughly the same voltage as when you hooked up the DMMs. If you're not using a variable transformer, you should measure roughly (-)25VDC and (+)25VDC. The DBT should glow brightly, then immediately dim.

-

If you are using a variable transformer, gradually increase the voltage to approximate your mains voltage. You should measure approximately (-)25VDC and (+)25VDC. The DBT should remain dark.

-

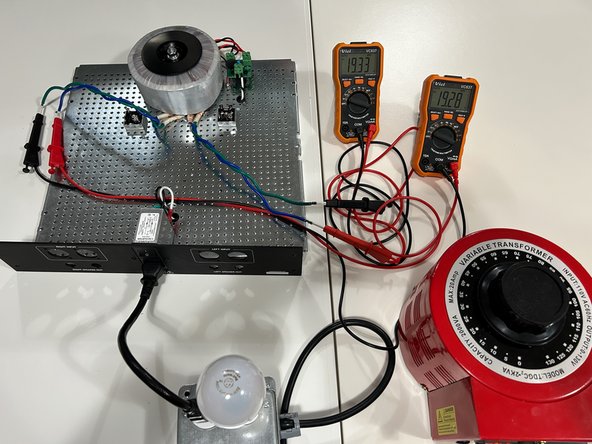

Photo 1 - Roughly 1/3 of the way to full output.

-

Photo 2 - Test complete.

-

Power down the circuit. Take notice of how slowly the voltage decreases. Again, there is no load on the PSU, and there are no bleeder resistors to drain the capacitors. Disconnect the red test probes.

-

Bleed / discharge the capacitors to below 2V. If you are unsure how to do this safely, consult an expert.

-

-

-

Ensure you follow previous safety practices!

-

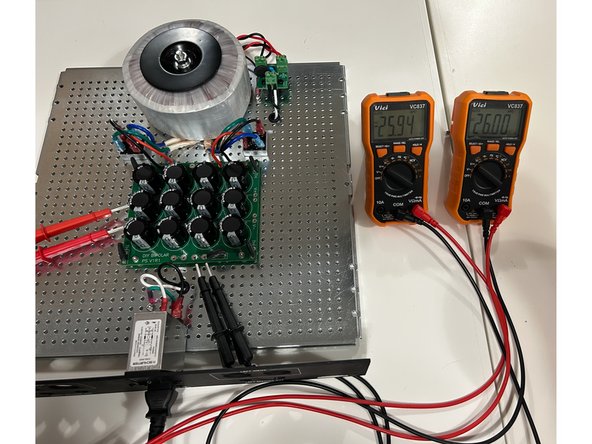

Connect the red probes to the V+ and V- pads for the right channel and repeat the process.

-

Note - per previous steps, the testing displayed was conducted with a DBT and a variable transformer in place.

-

Photo 1 - Roughly 1/2 way to full output.

-

Photo 2 - Success! Full output voltage.

-

Note - the final voltage from the variable transformer was not exact. The difference in the DC output from the left channel is not a concern.

-

Disconnect all power, and remove the test leads.

-

Bleed / discharge the capacitors to below 2V. If you are unsure how to do this safely, consult an expert.

-

-

-

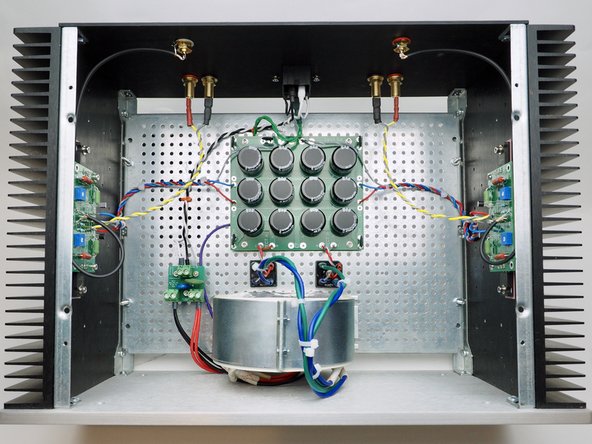

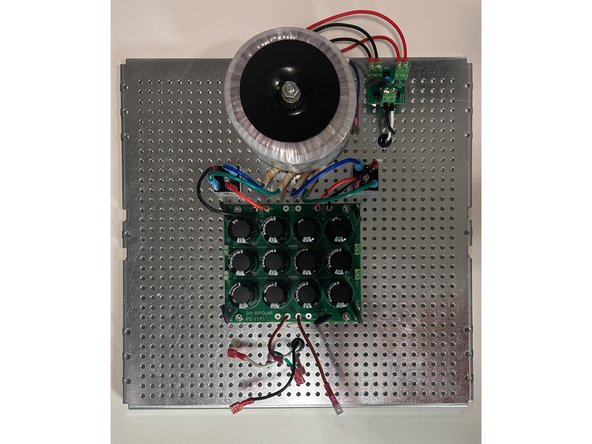

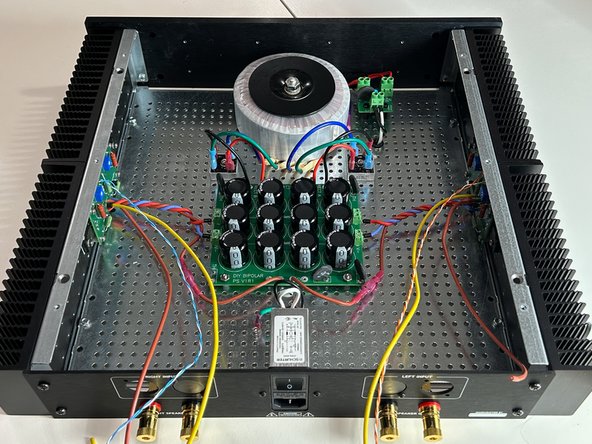

Now is the time to tighten all the nuts and bolts / connections you may have left loosened just in case you wanted to move anything around.

-

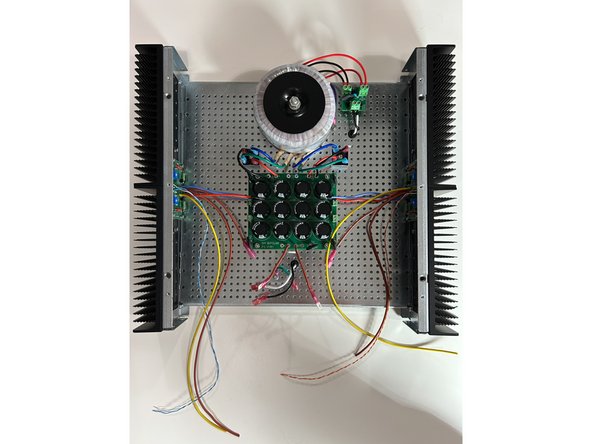

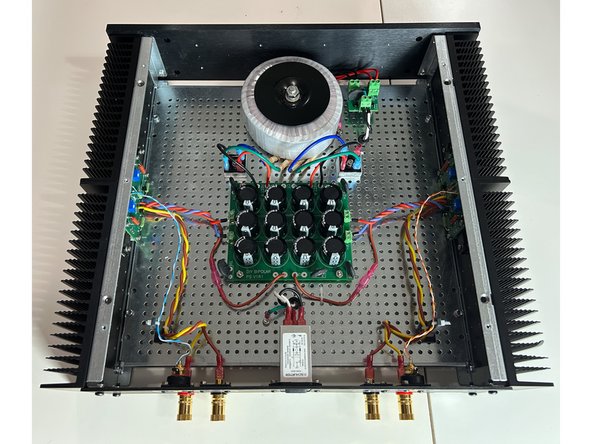

Photo 1 - Complete PSU assembly.

-

Triple check all your connections to ensure they are secure.

-

Triple check to ensure that all leads, wire-ends, or other components on the bottom of the PSU board have adequate clearance above the perforated baseplate.

-

Check the resistance between the RECTA pads and the baseplate. It should measure O.L. Check the resistance between the RECT B pads and the baseplate. It should measure O.L.

-

-

-

If this is your first linear PSU build, congratulations!!!!

-

If this is your 100th PSU build, congratulations.

-

If you haven't already, take a break. Now is a good time to relax.

-

-

-

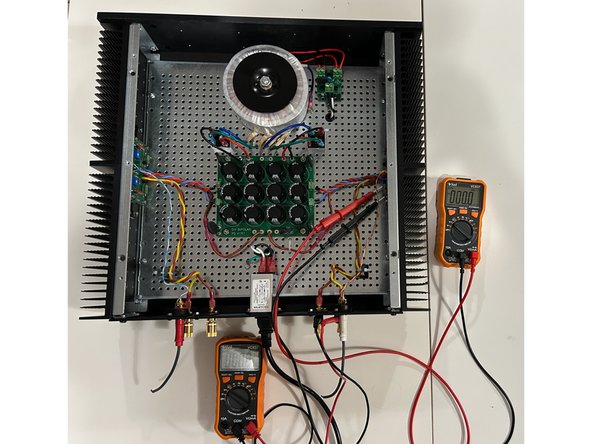

Everyone develops their own build sequence. For this build, an easy initial test of the amplifier boards was done to ensure there were no major problems before proceeding further. It's much easier to correct any errors before everything is in the chassis.

-

Collect your heatsink / amplifier board assemblies, lay them as they will be mounted to the perforated base plate and estimate the wire lengths from the amp boards to the PSU. Remember, you'll be twisting the V+ and V-. You can try to get it exact if you like, but it is safer to have excess wire.

-

Trim and terminate (as appropriate) the V+, V-, and GND wires.

-

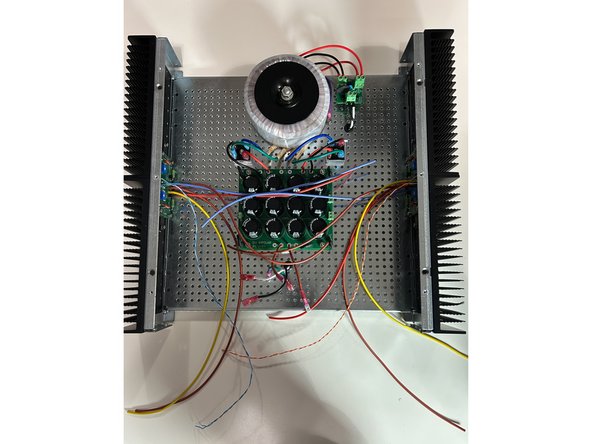

Photo 1 - Initial wiring mess.

-

Photo 2 - V+, V-, and GND wires trimmed / terminated. No need to address input or speaker wiring at this point.

-

Photo 3 - Quick Check that it all fits and connects. Note - It doesn't need to be perfect at this point unless you're directly soldering to the boards.

-

-

-

These next steps seem to cause the most problems with new builders. Please read Steps 64 through 66 over and over until you are confident in your process. Ask questions in the forum if there are any concerns or if you need clarity.

-

With the mains power disconnected, wire one channel of the amplifier board to the power supply; V+, V-, and GND. (If you had both channels connected previously to rough in your wiring, disconnect the V+ and V- from one amplifier board.) You should test one channel at a time.

-

Connect your variable transformer and/or DBT, as appropriate. You should still have the low amperage fuse in the PEM as protection.

-

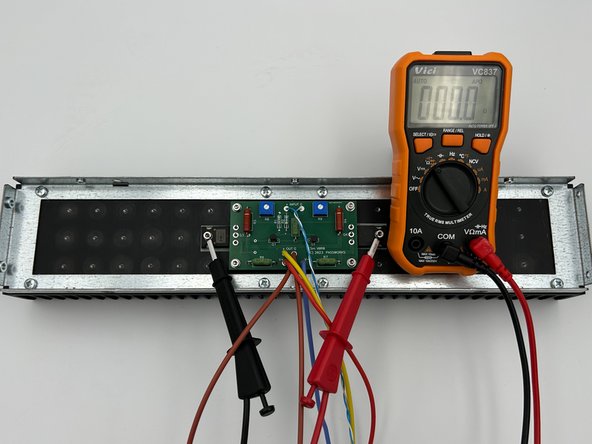

Photo 1 - Prep for initial testing of one amp channel. 2 DMMs, DBT, Variac, one channel wired to PSU.

-

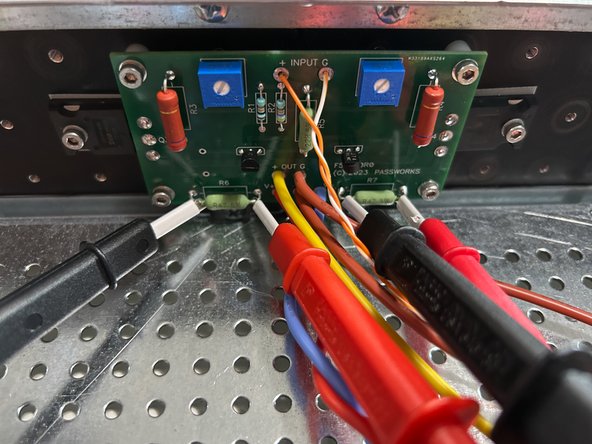

Triple check that both pots (R8 and R9) are turned fully counter-clockwise. Connect a DMM across R6, and connect a DMM across R7.

-

Photo 2 - Pots fully CCW. Probes across R6 and R7. It is STRONGLY recommended to use probes with "j-hook" / "mini grabber" leads. It is a tight area in a 2U build. Ensure you do not short the probes between the resistor legs and any other components or the chassis.

-

-

-

By this point, it is critical that you've ensured that your PSU is built properly and is delivering roughly +-25VDC (unloaded). If you are unsure about your PSU operating properly, double check your PSU voltages before proceeding.

-

Validate one more time: V+ and V- are properly connected. Pots are fully CCW. Variable transformer is set to minimum voltage (if applicable). DBT is in place (if applicable). DMMs set to DCV and probes across R6 and R7.

-

Make sure you are in a place where you can de-energize (turn off) the circuit quickly and safely if you smell smoke, see sparks, or observe anything concerning.

-

-

-

Power the circuit. If you are using a variable transformer, slowly increase the voltage until you reach full mains voltage.

-

You should see <1mV on the DMMs. If you see anything above 1mV, turn it off and seek assistance.

-

Keeping a very close eye on your DMMs - Slowly and gently turn each pot clockwise using very small increments. Alternate between pots after each tiny turn. You will have a zone where turning the pots will not have an effect. GO SLOWLY If you see either DMM rise above 30mV turn the pot back until both DMMs read below 20mV.

-

Once the DMMs are both reading between 15mV and 20mV, pause. Make sure both pots when turned gently clockwise raise the voltage across the resistors. Make sure each pot when turned counter-clockwise reduces the voltage across the resistors.

-

If either pot does not have an effect on the DMM reading, pause and seek assistance.

-

Power down the circuit. Return both pots to fully counter-clockwise. Disconnect the V+ and V- connections to the power supply.

-

Connect your V+ V- and GND connections from the other amplifier board to the power supply and repeat the initial check procedure starting back at Step 62.

-

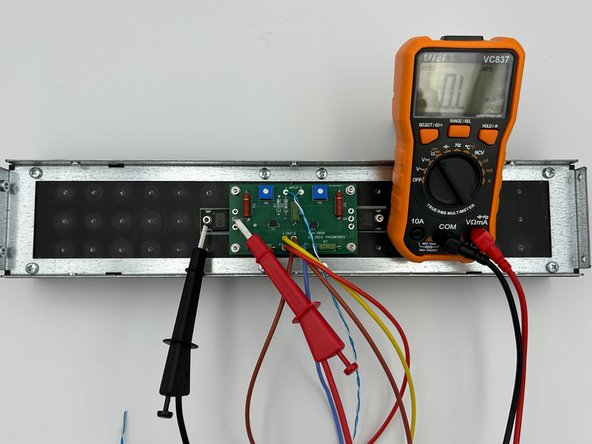

Photo 3 - Powered with full mains voltage to PSU => full DC voltage at the power supply. Pots carefully adjusted. DMMs indicating between 15mV and 20mV across R6 and R7. Success!

-

-

-

Congratulations. You're most of the way there. It's the perfect time for another break and a happy dance. Chances are, you're going to hear music soon.

-

-

-

Feel free to choose your own adventure, but the following steps seem to work well for a number of builders. Some of your decisions will be based on the chassis size you've chosen along with the connection types you've chosen.

-

The order for this build was to install the binding posts and input blanks for the back panel. Then, the front panel was installed. All wiring was trimmed to length, terminated, and dressed as appropriate.

-

A reasonable method when using Neutrik D-type jacks is to install them from the inside. This allows the input wiring to be soldered to the jack prior to installing the jacks on the back panel. For many people, that is an easier installation method. Plus, it looks spiffy. Feel free to do what works for you.

-

Finalize wire lengths. Attach the back panel. Trim, terminate as appropriate, and connect / solder as appropriate all mains wiring, speaker wiring, and input wiring.

-

Photo 1 - Back panel with input blanks (included in the back panel parts kit) and binding posts (optional with the back panel parts kit) installed.

-

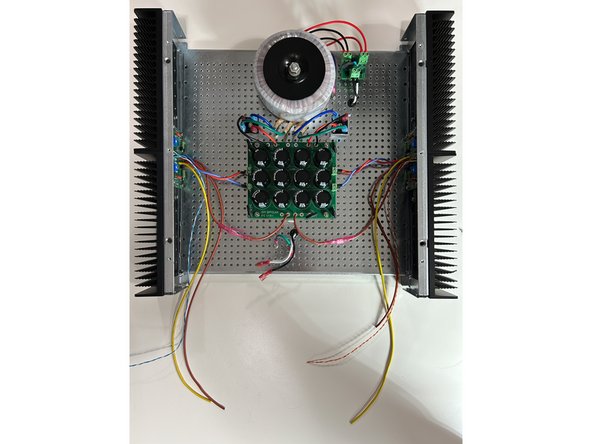

Photo 2 - Front and back panels installed. Amplifier boards connected to power supply with wires dressed. Input and speaker wiring ready to connect.

-

Photo 3 - Final wiring. Note - this build uses some fantastic wire management 'towers' courtesy of fellow DIYer, Birdbox.

-

-

-

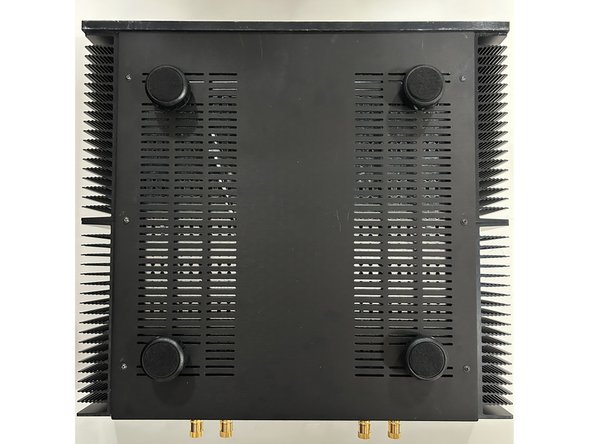

Install the feet onto the bottom panel of the chassis, and install the bottom panel.

-

Photo 1 - Bottom Panel Installed

-

Test the fit of the top panel, but don't install the top panel yet.

-

Now is the perfect time to double / triple check that the top panel will not under any normal circumstances make contact with the transformer mounting bolt. Consider a pet resting on a warm amplifier lid. If you have any concerns, a carefully placed piece of Kapton tape (non-conductive material) may ease your mind.

-

-

-

Install your final value mains fuse. This will primarily depend on your mains voltage and the toroid you've chosen. In this example, the mains is 120VAC, and we are using a 200VA transformer. So, a 2A slow-blow fuse was chosen. 200VA / 120VAC = 1.67 + a bit of headroom gets us to the next common rating of 2A.

-

It is recommended to use a DBT / current limiting and/or a variable transformer to triple check that all wiring was installed properly. It takes very little time to add a layer of confidence.

-

A cautious approach may be:

-

With the DBT in place, slowly bring the circuit to full mains voltage. Check the V+ and V- readings for both channels. The DBT should remain dim. Power down the circuit. Allow the caps to drain (wait a few minutes).

-

Power the circuit immediately to full mains. The DBT should immediately glow brightly and dim quickly.

-

Ensure both pots (R8 and R9 are still fully CCW. Connect the DBT / Variable transformer as appropriate. Bring the circuit to full mains voltage and ensure that both channels of the power supply are operating at roughly +- 24V. If not, STOP and troubleshoot / ask for assistance.

-

Photo 1 - (+)24V66 check on the positive rail for the left channel. The positive and negative rails for both channels were within a few tenths of a volt. Proceed! (Reminder, it is unlikely that your voltages will match those in the guide. It is only important that they are within a few volts of +- 24V and that the rails are roughly equivalent.

-

-

-

If you haven't already, now is a great time to determine your desired target bias current. As mentioned, this build is in a 2U chassis and will be a "lower bias" build.

-

In the Nelson Pass article, he demonstrates some calculations for determining the recommended bias current based on the heatsink size and desired maximum temperature. He mentions 1A1 for the 2U chassis. We will target 1A1 and perhaps adjust based on heatsink temperatures.

-

He shows the maximum bias current he tested with 24V rails to be 1A4 in a 3U chassis. Certain fearless amplifier builders have taken it a little further and have used larger chassis to control temperatures. Proceed at your own risk.

-

We can't easily measure the current through the output devices directly, so how is that calculated? Ohm's law. The voltage target across R6 or R7 multiplied by the resistance of R6 or R7 is the current through R6 / R7. In this case 1A1 * 0R47 => ~0V52. So, the target will be 0V52 across R6 / R7.

-

Calculate your required voltage across R6 / R7 and jot it down.

-

Target DC offset at the speaker terminals is <10mV.

-

This step takes an hour or more to do properly. Thermal equilibrium needs to be reached. So, don't start until you have some time to dedicate. NOW IS NOT THE TIME TO RUSH!

-

-

-

In order to allow as little noise into the circuit as practical while setting the bias and offset, it is advised to short the inputs during the bias and offset adjustments.

-

You can short the inputs any number of ways. My two favorites are:

-

Using "crocodile leads" to short the inner barrel of the RCA to the GND tab.

-

Using a set of "shorting plugs" that I fashioned from old RCA connectors. Here is how I did it:

-

Strip the outer insulation.

-

Twist the leads together.

-

You can check to make sure you've done it properly by ensuring that you have a very small (a fraction of an ohm) resistance between the Input (+) and Input (G) pads on the PCB.

-

-

-

You cannot set the final bias / offset with the DBT / current limiting in place. Remove the DBT if you have been using one. It is the builder's choice whether to use a variable transformer to set mains voltage or connect directly to a standard mains outlet.

-

This example shows 2 DMMs per channel. If you are fortunate enough to have 4 DMMs, you can alternate setting the bias and nulling the offset between both channels. If this is your first build, it is recommended to do one channel at a time.

-

Connect DMMs across R6 or R7 for one channel. Connect one DMM across the speaker terminals of the same channel. Again, the DMMs should be set to DCV and appropriate range. Short the inputs. You'll notice shorting plugs made from old interconnects in Photo 1. Crocodile clips can also be used.

-

Photo 1 - Ready to go.

-

Photo 2 - If you have followed all the precautions up to this point, you should be listening to music with your new F5M in a few hours.

-

-

-

Video 1 - We didn't have the budget to get Morgan Freeman to do the voiceover. This video demonstrates how to rough in the bias and offset.

-

Power on the amplifier. You should observe <5mV on both DMMs.

-

Similar to Step 66, SLOWLY turn both pots (R8 and R9). Small turn on R8. Small turn on R9. Back and forth. Pause as soon as you see the voltage across the speaker terminals (the offset) increase. Notice how turning the other pot affects the offset.

-

Continue slowly turning each pot CW. The offset will increase, then you null the offset with the other pot. Continue small turns back and forth. Soon, you will see the voltage across R6/R7 increase. You will notice that turning either pot clockwise increases the voltage across R6/R7.

-

Continue roughing in the bias and nulling the offset until you reach about 75% of your target bias current.

-

Once you have reached around 75% of your target bias current, power down the amplifier. Move your DMM probes. Rough in the bias for the other channel.

-

-

-

The goal of this step is to set the final bias and offset. It is wonderful if you have 4, DMMs. If not, it will just take you a little longer. PLEASE DO NOT RUSH. IT IS NOT RECOMMENDED TO MOVE PROBES BETWEEN CHANNELS WITH THE AMPLIFIER UNDER POWER IN ORDER TO SAVE A LITTLE TIME. IF YOU DON'T HAVE 4 DMMs, PLEASE DO ONE CHANNEL AT A TIME.

-

As mentioned, the bias current increases as the output devices warm up. So, being a little low is not a bad thing. Offset is very stable, relatively speaking and rarely wanders more than a few mV or even 10ths of a mV once the heatsinks are warm and at equilibrium.

-

Install DMMs across R6 or R7 and the binding posts per previous steps. Ensure that inputs are shorted. Rest the top plate / lid gently on top of the amplifier taking care not to yank on your probe leads.

-

Allow the amplifier to come to temperature and stabilize at about 75% of your target bias current.

-

Remove the lid and carefully, but quickly adjust each pot accordingly in an attempt to get close to your target bias current. Put the lid back on. Wait at least another 5 to 10 minutes. Remove the lid. Tweak. Replace the lid. Repeat until you're happy.

-

The bias current doesn't have to be perfect or perfectly match between channels. +- 5% is perfectly acceptable. A DC offset less than 10mV is perfect.

-

Photo 1 - Close enough to 520mV on both channels and less than 10mV of offset on each channel after allowing the temperature to stabilize. No changes in bias or offset for over 5 minutes. Success!

-

-

-

It is bad luck to screw the lid down before testing the amplifier with music.

-

Grab a pair of speakers that don't matter much to you or a single speaker to move back and forth. Connect the amplifier to the speakers and a source.

-

A phone, tablet, or any other battery-powered source is appropriate for initial testing.

-

Play some music. Listen for any noticeable distortion / snaps / crackles / pops or other breakfast cereal sounds. Keep it running for a day or two on test speakers. Check it with a mains powered source. Monitor the bias and offset (as done previously without speakers and a source connected) to ensure it is stable.

-

Ambitious DIYers may take this opportunity to also do some objective measurements.

-

Video 1 - It's a 'Lovely Day'.

-

Once you know the amplifier is stable over a period of days, screw down the top panel, place the amplifier in its new home, and enjoy your new F5M for years to come.

-

Congratulations on building the F5M.

A few things before you run off and start another project:

- This is a build guide by DIYers for DIYers. If you have any suggestions for improvement, notice any errors, or think something could be clarified, please post in the forums. Someone will be looking.

- Please post some pictures of your build in the forum. Nothing makes us happier than seeing completed builds and the creativity of DIYers around the world.

- Make sure to go to the forums and thank Nelson Pass for another amazing project.

- Last but not least, please click the button below if you completed the amp. It really helps the data dorks.

Congratulations on building the F5M.

A few things before you run off and start another project:

- This is a build guide by DIYers for DIYers. If you have any suggestions for improvement, notice any errors, or think something could be clarified, please post in the forums. Someone will be looking.

- Please post some pictures of your build in the forum. Nothing makes us happier than seeing completed builds and the creativity of DIYers around the world.

- Make sure to go to the forums and thank Nelson Pass for another amazing project.

- Last but not least, please click the button below if you completed the amp. It really helps the data dorks.

Cancel: I did not complete this guide.

6 other people completed this guide.